Automation plays a key role in Industry 4.0. Some factors which are increasingly prompting companies to digitize their processes are cost reduction, zero-defect quality and increased productivity but full automation often also means high investments.

In the interaction between man and machine, the focus will also continue to be on the human being. This is no easy task for companies due to the high standards of industrial safety and prevailing shortage of skilled workers.

A large number of variants, complex tasks and processes, and increasing quality, requirements are further challenges for successful process optimization.

With the assistance system ‘Der Schlaue Klaus’ (Smart Klaus), the German company Optimum data management solutions GmbH has developed a smart solution for this to succeed: in order to simplify and optimize manual inspection processes, the easy-to-integrate, camera-based assistant utilizes digitization.

The assistance system recognizes every step and assists the employee in real-time during the entire assembly process by combining industrial image recognition utilizing a high-resolution USB3 industrial camera from IDS and an intelligent database.

Even these complex processes become manageable according to the simple principle: Instructing - checking - confirming - documenting.

Application ‘Der Schlaue Klaus’

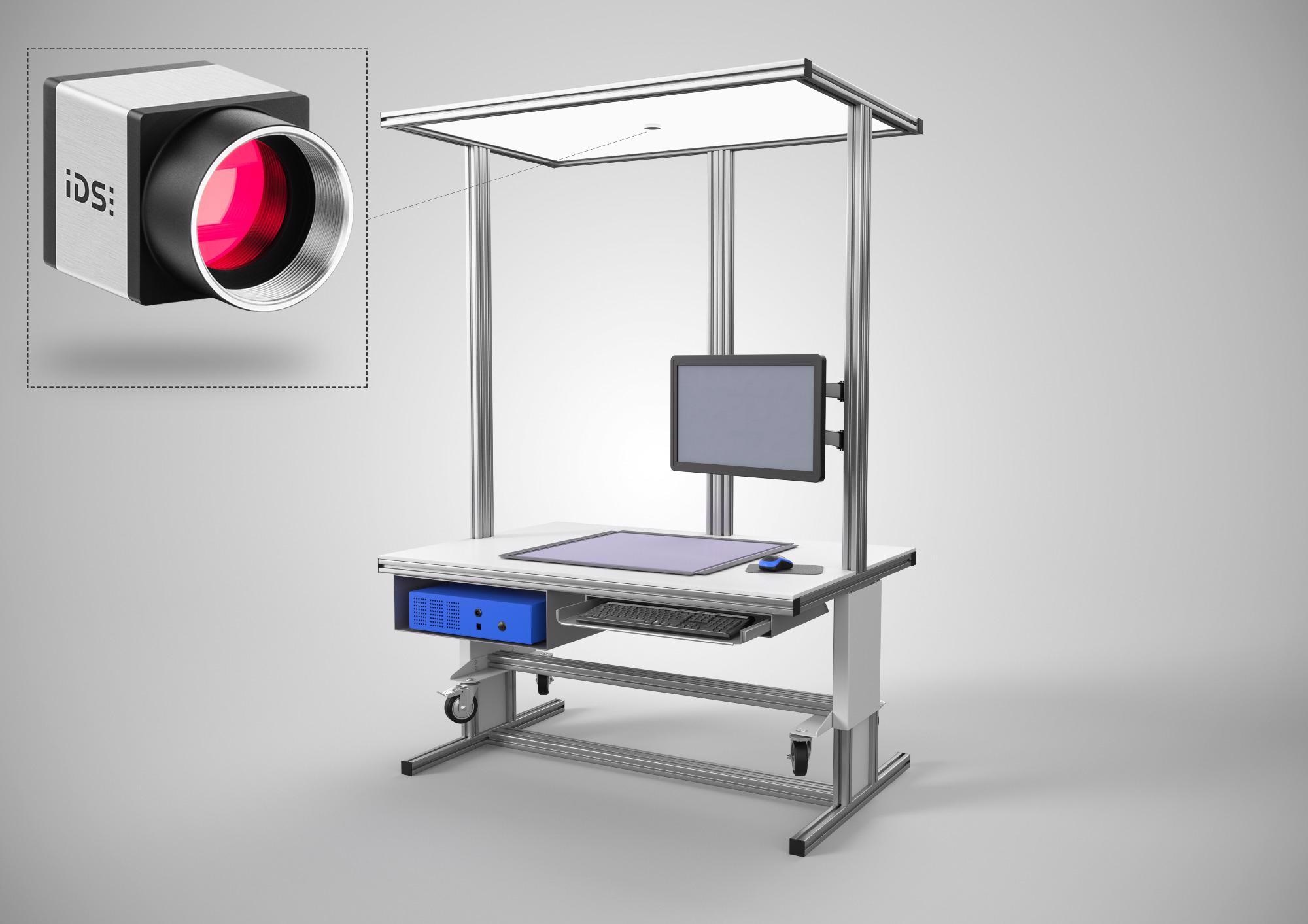

Employees are guided step by step with digital assembly instructions by the intelligent assembly assistance system ‘Der Schlaue Klaus’ (Smart Klaus). The worker scans the order document, and the assembly process starts. The workpiece or individual parts to be mounted are recorded by an IDS camera installed above the work table.

Error messages and operating instructions both appear on a touch monitor in real-time: The worker receives a confirmation after each successful work step. The system provides evidence of fault-free production once assembly is finished.

'Smart Klaus' assembly assistance system with USB 3 uEye CP industrial camera from IDS. Image Credit: IDS Imaging Development Systems GmbH

Wolfgang Mahanty, managing director of OPTIMUM data management solutions GmbH, explains, "The camera generates the digital shadow." All digital data of the process is recorded and processed, so when and how it is done. This permits the creation of a knowledge base and the subsequent transfer of knowledge to all.

Summarizing the demands on the camera, Mahanty says, "The camera has to capture many details and a wide range of variations and provide stable images. Sensory recognition must be reliable, i.e. the sensor must be able to cope with poor or changing lighting conditions."

The reason: "In today's factory, the employee should get as much daylight as possible, which can affect the quality of the recording."

No problem for the USB3 industrial camera UI-3590CP from IDS. To ensure outstanding image quality even in low light conditions, the light-sensitive AR1820HSSC00SHEA0 rolling shutter CMOS sensor from ON Semiconductor uses BSI ('back-side-illumination') technology.

Extremely high-resolution images with low image noise are produced even when capturing the smallest details. It attains a frame rate of 21 fps with a resolution of 18 MP (4912 x 3684).

Products are detected with deviations of 1 mm on DINA 3".

Wolfgang Mahanty, Managing Director, OPTIMUM Data Management Solutions GmbH

The small, compact size, in addition to the easy integration of the camera, also convinced the team of 'Smart Klaus.'

The intelligent assembly assistance system 'Smart Klaus' guides employees step by step with digital assembly instructions. Image Credit: IDS Imaging Development Systems GmbH

Mann + Hummel, The German, Ludwigsburg-based company and world market leader and expert in the field of filtration, also appreciates the benefits of the assistance system optimized with the IDS camera model.

The utilization of the ‘Smart Klaus’ is also relied upon by Peter Sawatzky, Technical Manager at Mann + Hummel.

During the final assembly of our filter components, many manual activities are required. This demands changing devices with very complex and, therefore failure-prone sensory queries. The assistance system has convinced us because we make far fewer mistakes.

Peter Sawatzky, Technical Manager, Mann + Hummel

New variants can be easily learned during work preparation and can be installed by the worker on the same day. "Our variant management has thus become much easier," says Sawatzky.

Another advantage is that the system can be very easily integrated into the respective production facility, and if the customer application requires it, even the utilization of a number of camera models is viable easily and cost-effectively.

With Klaus' help, employees are able to learn new procedures quickly and safely through the digital step-by-step instructions. The relief of the worker through the individual assembly assistance system, in addition to an easier work organization, enables a significant increase in productivity.

Easy integration into the respective production equipment, simplified variant management. Image Credit: IDS Imaging Development Systems GmbH

Assembly costs are decreased, and at the same time, complaint costs are minimized by the increased quality assurance. "Since 'Smart Klaus' has been supporting our workers during assembly, the number of complaints has fallen significantly," confirms Sawatzky.

Outlook

Assistance systems such as the one from OPTIMUM datamanagement solutions GmbH are increasingly accelerating processes and ensuring increased efficiency and quality, especially in the electronics and automotive sectors. Manufacturing processes are fully documented and can be traced and run almost flawlessly.

They help companies to increase productivity in this way and, if necessary, gain a competitive advantage. Simple, intuitive operation is the key basis for the successful introduction of Industry 4.0 and the associated. It is for this reason that Optimum is constantly working on how easily the system can be taught.

This is achieved by utilizing intelligent filters, CAD data, or even artificial intelligence. The possibility of virtual commissioning is a further step on the way to digitization. The assistance system must be designed so intuitively that every employee from the maintenance or work preparation department can use it himself.

Digitization is constantly advancing, and the requirement for solutions to increase quality and efficiency in the factory of the future is growing. It can be covered quickly and easily with individual, easily integrated assistance systems and intelligent image processing. An investment that pays for itself in a short time.

uEye CP - Incredibly Fast, Incredibly Reliable, Incredible Sensors

- Shutter: Rolling Shutter

- Sensor format: 1/2.3"

- Weight: 45 g

- Interface: USB 3.0

- Dimensions: 29 x 29 x 29 mm

- Model: UI-3590CP Rev.2

- Sensor type: CMOS

- Manufacturer: ON Semiconductor

- Connector: USB 3.0, Micro-B, screwable

- Frame rate: 21.0 fps

- Resolution: 4912 x 3684 px / 18.10 MPixel

- Applications: medical technology, industrial image processing, electronics inspection

Image Credit: IDS Imaging Development Systems GmbH

Client

Optimum specializes in intelligent image processing, which combines digitization, camera technology and database management. The IT expert team from Karlsruhe has been automating and optimizing the processes of leading industrial companies for more than 26 years.

Today, Optimum is a leading supplier in the field of camera-based assistance systems with its camera-based assistance system ‘Smart Klaus,’ which has won several awards.

This information has been sourced, reviewed and adapted from materials provided by IDS Imaging Development Systems GmbH.

For more information on this source, please visit IDS Imaging Development Systems GmbH.