Interview conducted by Sophia CoveneyMar 19 2024

Interview conducted by Sophia CoveneyMar 19 2024

Please can you introduce yourself and tell us about your role at Resolve Optics?

My name is Rob Watkinson and I am the Customer Support Manager at Resolve Optics. My role is to ensure that business customers receive outstanding support and all their needs are met. This may involve creating customer support policies and procedures for staff to adhere to, training and observing employees and answering customer queries.

Why are cameras essential pieces of equipment for use within the nuclear industry?

Cameras play an essential monitoring role to enhance safety in any radioactive environment as they allow visual inspection in areas where people cannot go because of the risks of exposure to radiation. Typical tasks for a camera in a nuclear environment include inspection of equipment, a process or fuel rods, to enhance safety and security as well as for simple surveillance of an area.

How do cameras need to be adapted for use in high radiation environments?

Exposure to higher levels of nuclear radiation will have a detrimental effect on most materials. Consequently, it is very important for nuclear cameras to only use materials that can withstand prolonged exposure to radiation or ensure the device has sufficient shielding to protect it. For example, standard camera lenses will turn brown (and lose throughput/clarity) after only a limited time in a nuclear environment - so only specialist radiation-resistant glass types can be used. Another key consideration is how you keep the camera sensor out of the direct shine path of the radiation. This is often solved by using fold mirrors that allow the image to be indirectly focused onto the sensor whilst keeping it shielded from the radiation.

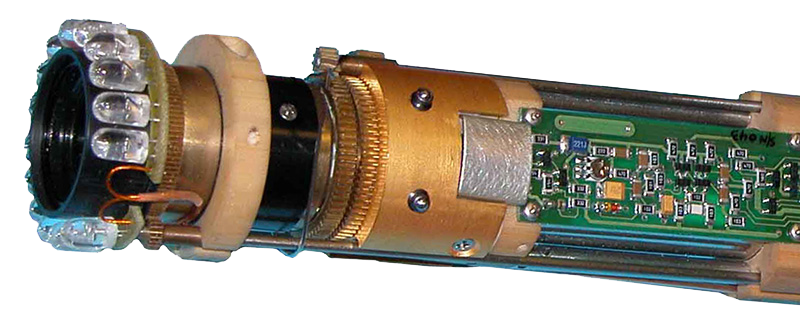

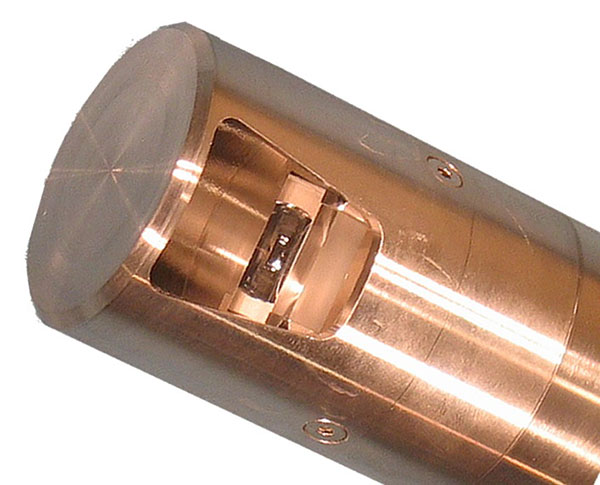

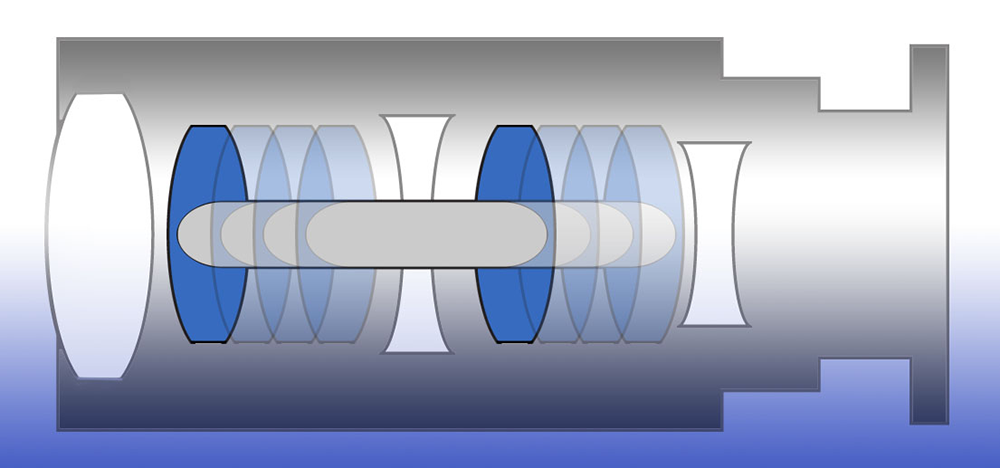

Tell us about the radiation-resistant lenses that Resolve Optics has developed and supplied to manufacturers of nuclear inspection cameras.

Over the last 30-years, Resolve Optics has developed both customer-specified and a growing range of off-the-shelf, radiation-resistant fixed focus and zoom lenses. Some of the most popular lenses are our 3x, 6x, and 10x non-browning zooms. While Resolve Optics has extensive experience in supplying fixed focus and zoom radiation resistant lenses for applications in Nuclear reprocessing and power generation – today our expertise is helping organizations operating in a growing number of different and interesting applications.

In medical research – Resolve Optics radiation resistant lenses form targeting elements in synchrotron radiation therapy machines and also in commercial x-ray instrumentation. All instrumentation, sensors, and cameras are subject to constant bombardment by radiation that will quickly degrade and make inoperative standard optical components in outer space. Spaceborne applications present a challenging environment, subject to radiation, where camera lens servicing or replacement is highly undesirable. In recent years a growing number of satellite manufacturers and international space agencies have selected Resolve Optics to supply them with a selection of high performance, radiation-tolerant zoom lenses because of our expertise in this area and willingness to work with them on adapting our standard 3x and 6x non-browning zoom lens designs to be ‘space ready’.

What features of these lenses enable high image resolution even in nuclear environments?

The nuclear environment itself has no direct effect on image resolution however the higher the resolution requirement of a lens the more glass that is required. The challenge with designing a high-resolution, radiation-tolerant lens is that there are only a limited number of optical materials available to choose from. Nearly all radiation tolerant optical materials have a yellow tint to them. The next problem you can run into is that the more glass you put into a system, to create the high-resolution image, the more this yellow tint will degrade performance. To address this challenge we introduced, in 2018, our Model 357-000, 10x non-browning zoom lens. This unique lens produces clear, sharp High Definition (HD) images free of the strong yellow tint that has traditionally been a limiting issue when using radiation-resistant lenses on color sensors.

Why do your lenses need to withstand high temperatures and how have you achieved this?

Used nuclear fuel contains lots of different radioactive elements and some of these elements decay very quickly. When they decay, they give off a lot of energy that can be absorbed by their surroundings, making it vital that lenses are able to operate at elevated temperatures. Materials used in lenses will expand and contract with changes in temperature and it is important that this movement is allowed for in the optical design. If this is not considered, it is possible that the lens will go in and out of focus as the glass moves with the temperature change. All optical elements within Resolve Optics radiation resistant (Non-Browning) lens designs are made using cerium oxide doped glass or synthetic silica enabling them to withstand radiation doses of up to 100,000,000 rad and temperatures up to 55°C without discoloration or degradation of performance.

How have the latest generation of Resolve Optics non-browning lenses overcome the issue of yellow-tinted images in CMOS cameras?

As mentioned previously, yellow-tinted images are a result of the traditionally strongly yellow-colored cerium-doped glass required to prevent the lenses from browning under prolonged exposure to radiation. While it is not possible to entirely remove all yellow from the image, if we are developing a lens for a color CMOS camera, we draw upon our knowledge of different suppliers to avoid the more yellow glass types and minimize the problem.

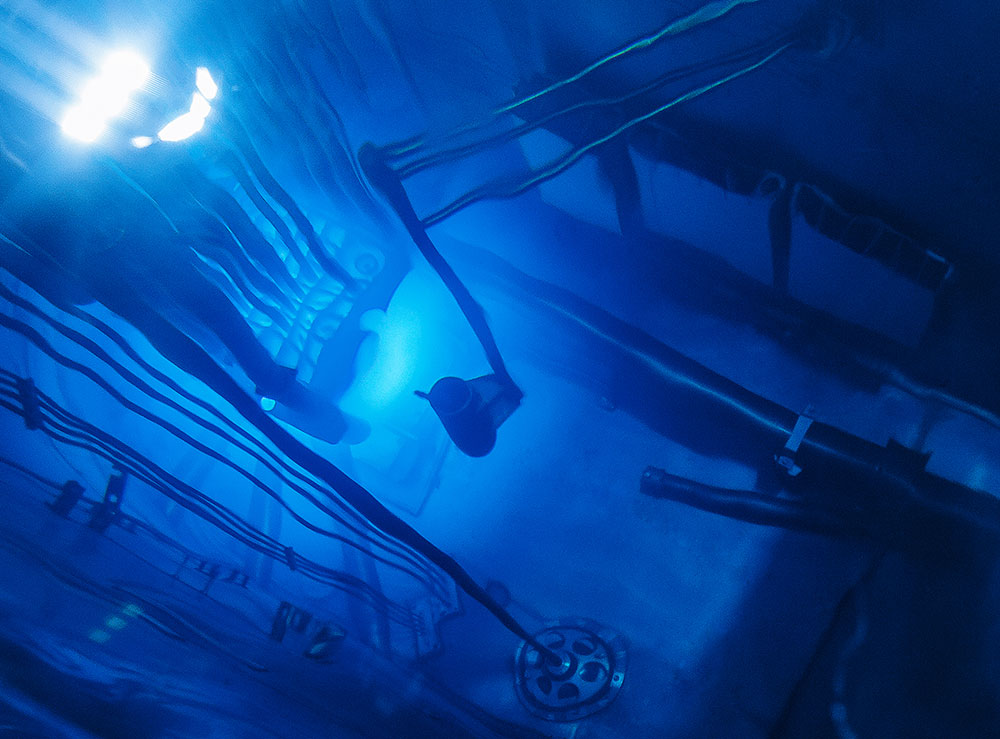

I understand that you have also developed a special UV zoom lens capable of viewing nuclear fuel rods through lengths of water – please tell us about this?

Spent nuclear fuel emits a faint ultraviolet light glow (Cherenkov radiation) when gamma rays from fuel assemblies interact with electrons in the cooling pond water, they are stored in. Resolve Optics has designed and supplies a UV zoom lens to enable a North American manufacturer of Digital Cherenkov Viewing Devices to remotely monitor this phenomenon through 10 meters of water. This lens also usefully incorporates a filter slide to easily switch from viewing visible to UV wavelengths without refocusing the lens.

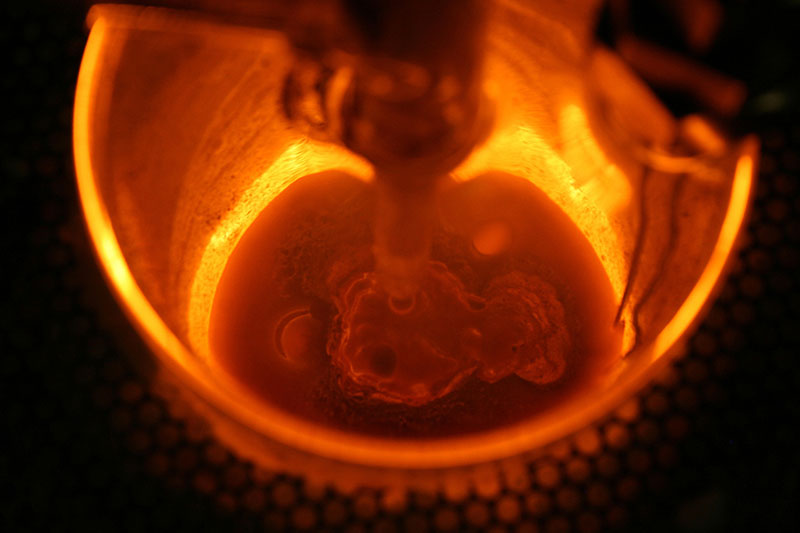

How have you applied your knowledge of radiation-resistant optical design to create endoscopes capable of providing efficient remote viewing within nuclear applications?

A: Resolve Optics is a well-established supplier of specialist endoscopic systems for hostile environments where radiation, extremes of temperature/pressure, or contact with corrosive liquids and gases would render standard products unusable. To enable inspection inside of operating furnace and boilers, Resolve Optics has supplied several specialist endoscopes to non-invasively analyze high-temperature processes including incineration, recycling, smelting, and chemical manufacturing. However, due to relatively high cost – endoscopic inspection systems are only used in nuclear applications where the high levels of radiation or temperature near the process would make camera operation almost impossible.

Has Resolve Optics got any development projects in the pipeline aimed at further helping improve nuclear inspection?

We are currently developing a new lens known as an optically compensated zoom. This design uses a relatively simple push-pull mechanism and as a result does not require that large number of complex, tightly tolerance parts that are typically required for a zoom lens. This much simpler design makes this new lens particularly suited for harsh environments such as are often found in the nuclear industry.

What do you think the future of nuclear inspection will be and how will Resolve Optics be a part of it?

The nuclear industry is highly regulated and consequently, change happens relatively slowly compared to some other sectors. In recent years – trends we have noted include an increasing demand for high-resolution radiation-resistant lenses as well as lenses optimized for color sensors.

Where can readers find more information?

For further information on radiation-resistant lenses please visit www.resolveoptics.com/radiation-resistant-lenses-3/. Alternatively, you can follow Resolve Optics on social media – see https://www.linkedin.com/company/resolve-optics-limited/

About Rob Watkinson

Customer Support Manager - Rob Watkinson is driven by his desire to ensure that business customers receive outstanding su pport and all their needs are met in a timely fashion. He works at Resolve Optics Ltd - a world-leading specialist lens designer and manufacturer of radiation-resistant lenses and optical products to strict quality and target price guidelines.

pport and all their needs are met in a timely fashion. He works at Resolve Optics Ltd - a world-leading specialist lens designer and manufacturer of radiation-resistant lenses and optical products to strict quality and target price guidelines.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.