The advent of digitalization and the development of Industry 4.0 have resulted in ever-evolving internal logistics requirements, with internal traceability - the tracking of goods in a production facility or warehouse - playing an increasingly key role.

Image Credit: IDS Imaging Development Systems GmbH

Both consumers and manufacturers are paying more attention to product safety and quality. They are also making the avoidance of potentially expensive and reputation-damaging complaints a key consideration.

The use of automated systems can help optimize goods control while simultaneously helping to facilitate and accelerate operator activities –saving both costs and time.

A notable example of the effective implementation of an internal traceability system in intralogistics can be observed at Schnellecke Logistics' Dingolfing site in Germany.

This site employs a scalable quality assurance solution from Pose Automation GmbH in Kleve, using this to deliver thorough photo documentation as part of its incoming and outgoing goods inspection processes.

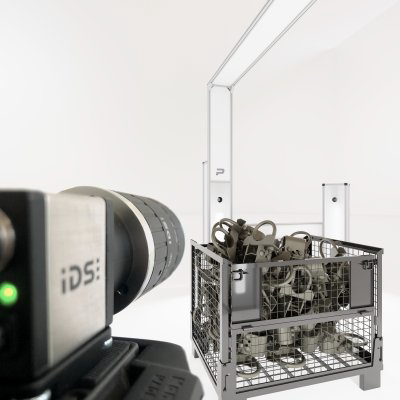

The P.Portal utilized in a logistics hall enables the analysis and documentation of goods' condition, leveraging the power of bright USB3 Vision industrial cameras from IDS.

Application

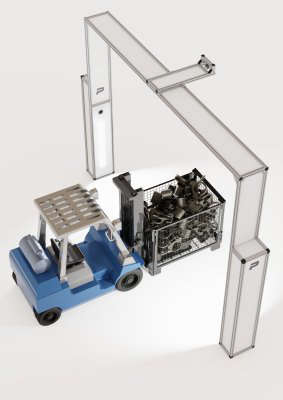

Schnellecke uses the P.Portal to inspect containers filled with components, photographing these to record documentary evidence used in the event of any complaints. Employees have historically performed this task manually using digital cameras.

Now, four cameras from the uEye CP family each take photographs of corresponding containers.

A trigger sensor ensures that these photographs are taken accurately and automatically, with a PC-based multi-camera system both displaying and storing this image data.

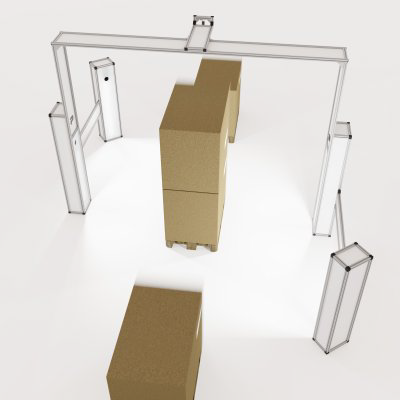

The cameras are attached to a bridge-like structure which the containers pass under as they are photographed and documented.

A distance sensor is used to prompt the automatic photographic of containers from four sides as they pass through – front, rear, left and right.

Photo portal with freely selectable camera positions. Image Credit: IDS Imaging Development Systems GmbH

The positions of the cameras can be freely selected – in this example, they are to the left and right of the portal.

Two lateral portal extensions ensure that all pictures can be taken simultaneously while the use of the optional Smart Light module offers intelligent light control for the image capture process, reducing energy usage and costs.

As Anne Hofbauer - Schnellecke Logistics' Lean Manager - explains: "The system meets all our requirements. It is also stable in continuous use."

The image processing components are ideally suited to this task. Individual, high resolution photographs are taken of passing trams and their wagons, with processing and order numbers documented to ensure comprehensive traceability.

A short exposure time of 1 ms ensures that even high train speeds can be photographed effectively.

The sensitive cameras thus capture the image material without motion blur and guarantee us complete traceability, as the images are of the same quality throughout and all the required sides of the containers are photographed.

Anne Hofbauer, Lean Manager, Schnellecke Logistics

USB3 Vision industrial cameras from IDS reliably detect passing containers even at high train speeds. Image Credit: IDS Imaging Development Systems GmbH

Sebastian Pose – Pose Automation's Managing Director – considers the camera's speed, resolution and light sensitivity to be among its most important selection criteria.

The U3-3890CP model was therefore selected for this standardized application.

This USB3 vision camera integrated for Schnellecke is ideally suited for tasks that necessitate a perfect result at extremely short exposure times.

It boasts a high-resolution 12.00 MPixel sensor – part of the Sony STARVIS range – which offers excellent light sensitivity and low noise due to its use of BSI (back-side illumination) technology.

The uEye+ camera is also able to offer extensive pixel pre-processing and features an internal 120 MB image memory for buffering image sequences, making it an ideal choice for use in multi-camera systems like the P.Portal.

Basically, the traceability solution P.Portal is designed for the flexible use of different IDS camera models. This enables us to offer our customers a wide range of economic applications. All in all, IDS cameras are characterised by their robustness and particularly easy integration into our systems. The integration is done with the help of the convenient IDS peak software development kit.

Sebastian Pose, Managing Director, Pose Automation

Software

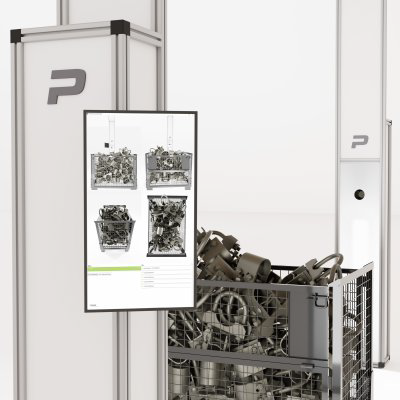

Each container taken from four sides is displayed in real time on the monitor. Image Credit: IDS Imaging Development Systems GmbH

Software developed by Pose Automation allows the real-time storage of all acquired images in the client's system, along with the date and time.

"What was important to us in the development of the software as well as the overall system was the high degree of automation of the photography process. In addition, P.Portal offers face pixelation with deep-learning technology and is thus DGSVO-compliant," Sebastian Pose highlights.

Modular extensions are also available, including the 'Smart Light' green technology employed in the example presented, whereby uniform lighting is provided for a passageway that switches on and off automatically.

Further modules are available, including 'Code Reading', 'Booking Live' and 'Smart Recording.'

Image Credit: IDS Imaging Development Systems GmbH

The system offers several clear advantages:

- Transparency is available in the event of a complaint. Photographic evidence can be provided to rapidly determine whether any damage was present at handover or whether this occurred later. This saves time and avoids expense.

- Comprehensive documentation is ensured. The P.Portal photographs the condition at handover, with the logistics process seamlessly recorded by the cameras.

- Order and product traceability is provided with optional features allowing the packaging labels with bar, DMC and QR codes to be automatically read and linked. This can also be integrated with the customer's own booking system.

- The process is time neutral, with rapid photography not taking any extra time – a crucial consideration in busy operations.

The automation of the photo process makes the process flow time-efficient and leads to a reduction in the workload of the employees, as well as ensuring the process with regard to complete documentation.

Anne Hofbauer, Lean Manager, Schnellecke Logistics

Outlook

Product quality must always be ensured. The scalable quality assurance provided by P.Portal ensures thorough analysis and documentation of the condition of goods and products – during both incoming or outgoing goods inspection, as well as during ongoing production.

Where intralogistics processes can be automated with the help of image processing, there is a great deal of potential for quality improvements, enhanced efficiency and cost savings.

Using the most effective solution assists companies in further developing their processes and improving results, regardless of industry, sector or application.

This information has been sourced, reviewed and adapted from materials provided by IDS Imaging Development Systems GmbH.

For more information on this source, please visit IDS Imaging Development Systems GmbH.