In this interview, AZoOptics talks with Chihiro Iitsuka about high-performance polarized films WGFTM and its benefits and applications.

What are high-performance polarization films?

High-performance polarization films are films that show exemplary performance both in parallel transmittance and Crossed Nicols transmittance. Some polarizers have low parallel transmittance; therefore, their appearances are often dark. Conversely, high-performance polarization films, WGFTM, allow you to see the opposite side through it. Evidence suggests that WGFTM shows high parallel transmittance.

How is this technology used?

The primary application is the anti-reflection effect. When image inspection is conducted, reflected light may be an issue. Polarization technology is instrumental in those cases, and you can take advantage of various industrial fields.

Can you explain what WGFTM is?

WGFTM is the film-based wire grid polarizer. Its Aluminum wire grid structure brings a high polarization separation performance in various wavelengths, not only VIS but Infrared (IR) or longer. WGFTM can be manufactured by a continuous roll-to-roll nano-imprinting process.

Image Credit: Asahi Kasei

What sets WGFTM apart from similar technology?

WGFTM is a reflective polarization film. Therefore, it has excellent heat resistance compared to absorptive polarizers. We can take advantage of this property for applications that require high-temperature durabilities, such as automotive use or inspection tools using strong light intensity.

Image Credit: Asahi Kasei

WGFTM is aluminum grid polarizer. Why has this technology been challenging to implement?

For the polarization effect to appear, it is necessary to make a nano-scale structure, a wire grid, on the film. We make a 100 nm pitch structure on the film. Although film with wire grid film can be manufactured individually, in-plane fluctuation tends to be wider, and it can be expensive. It is challenging to make nano-scale structures through a continuous process. The advantage of our technology is that we manufacture films with nano-scale structures through a roll-to-roll process.

Can you describe some of the unique properties of WGFTM?

WGFTM has various unique properties, such as a reflective polarization film with low heat absorption, which is usable in transmission and reflection. It also has a low AOI (angle of incidence) dependence and shows stable optical performance even at wide AOI, such as PBS (Polarized Beam Splitter).

Its effective range is extensive, from VIS to IR and beyond, and the anti-reflection effect with IR image sensors has been used in several industrial fields. Furthermore, its reliability is excellent in high temperature and humidity conditions; WGFTM can even be used in an environment where conventional polarizers cannot. It is popular in automotive use or high-brightness lighting.

It has flexible and excellent processability, with a range of processing options, such as cutting into complicated shapes, bonding to other materials, and curved surface molding. We can offer it as a processed product, for example, a camera filter and panel.

What industries will benefit the most from this product?

WGFTM is applicable in various industries, primarily industrial inspection cameras and biometrics. One of the most significant advantages of WGFTM is to polarize even Infrared (IR). Imaging inspection with IR is beneficial since it would be possible to recognize the defect without destruction, even though we cannot find it in the visible range.

IR usage for inspection has also been spreading recently. Our WGFTM has already been applied in the industrial imaging inspection market for packaging medicine, fruit sorting machines, packaging film for food, PCB (printed circuit board) inspection, and so on.

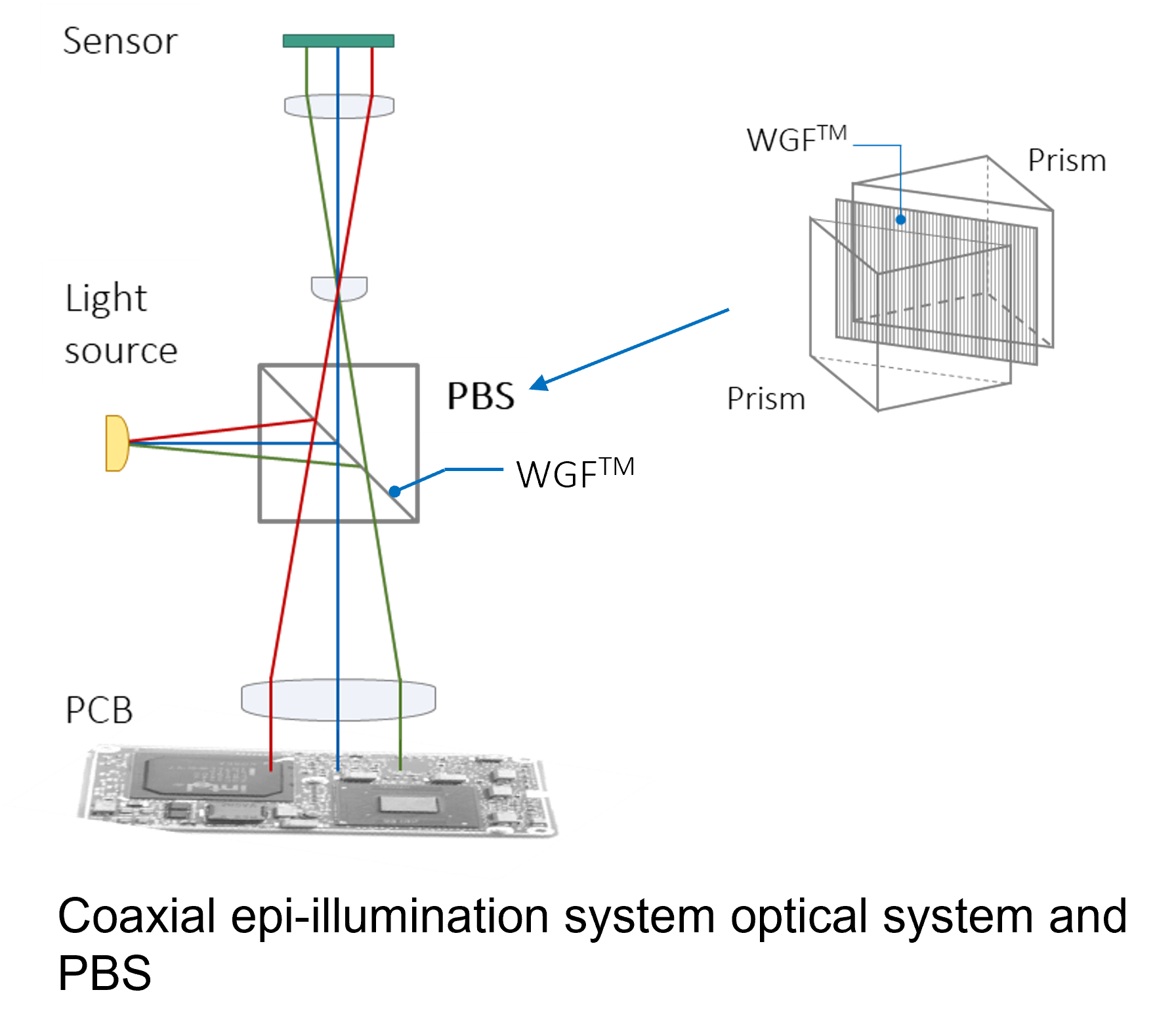

The advantage of a low AOI dependence also contributes significantly to PCB inspection. The polarizing beam splitter, PBS with WGF™, has stable optical performance in a wide range AOI.

This property is effective in Coaxial epi-illumination system optical systems. Even in an optical system with reducing lenses, the color and polarization do not partially change, which naturally improves the quality of imaging inspection.

If you are already using a half mirror, you can expect an improvement in brightness by replacing it with WGF™ PBS.

Image Credit: Asahi Kasei

We can also provide you with other processed products as with PBS, these products include the WGF™ camera filter and the WGF™ panel. The WGF™ camera filter supports wideband imaging from CMOS to InGaAs. You can attach it to your camera lens unit easily.

It is a convenient double structure with a fixed frame that can be attached to a lens as it is and a rotating frame that allows you to adjust the polarization axis freely. When you use the WGF™ camera filter, we recommend you also use the WGF™ panel for a light source.

The WGF™ panel - a WGF™ sheet laminated on glass - can polarize the light source and is easier to handle than a WGF™ sheet itself. One of the benefits of WGF™ is excellent reliability in high temperatures.

Conventional polarizers are often deformed or damaged when used for high-intensity polarized lighting. By comparison, WGF™ can be used with high-intensity halogen lighting.

Furthermore, the brightness can be improved by recursively using the reflected light on WGF™. You can use the WGF™ panel for the IR light source, and it is also helpful for a VIS light source; thus, it can also be adopted in VIS conditions.

WGFTM is also applicable in biometrics, particularly for the palm veins, as their patterns are individual to each person, and their recognition accuracy is high. This profiling would avoid the embarrassment of the facial biometric recording process and thus make our smart life more comfortable. Our WGFTM can significantly contribute to this technology.

Regarding future technology, WGFTM has been tested for pancake lenses by various companies. Downsizing the VR headset has been one of the main challenges. Optical design with Pancake Lens, which can make a headset smaller, will probably be standard in the next generation.

We have succeeded in developing the WGF™ lens and WGF™ 3D lamination on lens, which have been getting requests from several VR headset developers.

Furthermore, WGFTM has already contributed to AR glasses as WGF™ PBS. AR Glasses in the current market use LCOS for their displays, which structurally require PBS. PBS using WGF™ has been used by many customers for years because it provides stable optical performance even for a wide range of AOI.

What are driver monitoring systems, and how could WGFTM play a role in this technology?

Driver monitoring systems check the driver's condition to confirm the driver is awake. Although automated driving has been improved, we still have to drive ourselves to some extent. As a result, drivers are more likely to fall asleep, which is very dangerous. Therefore, Driver monitoring systems are necessary.

The system usually uses IR for imaging, and there is often specular light that prevents the determination of the driver's condition. However, if you use WGFTM, you can cut specular light effectively, and the image of the driver's eyes is clarified. As a result, recognizing whether the driver is awake or asleep becomes easier and more reliable.

What is LIDAR, and how can WGFTM help improve this technology?

LiDAR, light detection and ranging, is a system that measures distance and direction through laser light. When LiDAR Systems are used by multiple devices or machines in the same area, interference between LiDARs can happen when the beam sent from one is scattered and then returned or transmitted directly to another LiDAR sensor.

The prevention of scatter interference and subsequently improved object detection is just one of the benefits of WGFTM for LiDAR systems. WGFTM can also optimize the signal-to-noise ratio, enhance sensor performance, and prevent crosstalk between overlapping LiDAR systems.

How does WGFTM meet Asahi Kasei's commitment to the development of society?

WGFTM has many possibilities in various fields, such as inspection. Inspection improvement would raise yield, and it could help to reduce CO2 emissions. Additionally, biometrics could realize both convenience and high-security levels simultaneously. Furthermore, the light and small VR HMD (Head Mount Display) and sophisticated AR glasses allow for a safe and efficient working style.

WGFTM is also used as a fundus/retinal examination tool in the medical field. Asahi Kasei's group mission is to contribute to life and living for people worldwide, and the group slogan is Creating for Tomorrow. WGFTM meets this by making life and living more convenient and comfortable.

New applications with WGFTM have been founded, but we have been looking for stages where WGFTM can provide more solutions, and we will welcome new ideas and discussions anytime.

new ideas and discussions anytime.

About Chihiro Iitsuka

Chihiro Iitsuka graduated from Tohoku University with a Master’s Degree in Applied Chemistry. Now Chihiro works at ASAHI KASEI CORPORATION and is in charge of sales and marketing of WGFTM products. She works on promoting the WGFTM for IR applications and suggests solutions for customers. As IR's application range is wide, she covers various fields such as industrial inspection, sorting machines, biometrics, and medical device.

This information has been sourced, reviewed and adapted from materials provided by Asahi Kasei Corporation.

For more information on this source, please visit Asahi Kasei Corporation.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.