Over the past twenty years, multi-layer thin-film filters (TFF) have become a widely used form of an optical element, powering numerous, varied photonics applications and markets within the visible (VIS: 400-700 nm), near-infrared (NIR: 700-1000 nm), and short-wave infrared (SWIR: 1000-3000 nm) wavelength ranges.

Changes in optical filters have been driven by two primary application areas:

- Facilitating amplification gain flattening, wavelength division multiplexing, and dispersion compensation in fiber-optic telecommunication networks developed for high capacity applications (1300 nm - 1600 nm)

- Delivering more signal with less background to spectroscopists and microscopists studying the existence and concentrations of certain chemical species through properties like fluorescence or Raman scattering (400 nm – 1200 nm)

To meet these and other application needs in the VIS/NIR/SWIR wavelength range, optical filter technology has seen real progress in terms of filter shape complexity, cost durability. Filter manufacturers have moved away from the use of soft coatings which rely on lamination to protect filters from the elements.

They have also abandoned the commonplace expectation that these would need to be replaced as they wear out or fade.

The use of contemporary, energetically sputtered coatings results in filters which are engineered to accommodate use in even the most rigorous environments, while ensuring long product lifetimes.

In-situ optical monitoring with automated coater control and dynamic design adjustment has allowed for the production of optical filters which possess progressively more complex shapes. These also provide an enhanced signal to noise while enabling multi-band spectral performance.

Better coating uniformity coupled with more efficient machine operation (achieved via load-lock systems) has not only increased the complexity of filters which can be produced, but these improvements have also helped reduce their cost.

Alongside this astonishing growth in optical filter technology, demand has developed in spectral regions beyond the traditional VIS/NIR/SWIR ranges.

While it was previously only the realm of the military and defense industries (which are less sensitive to cost implications), detectors designed for use in the mid and long-wave IR (MWIR: 3-5 µm/LWIR: 8-12 µm) wavelength ranges have become considerably less expensive, increasing their availability and use in more regular commercial applications.

These applications and markets include security, surveillance, environmental monitoring and analysis, industrial process control, and medicine; each establishing a new set of optical filter requirements.

Beyond Thermal Imaging

Functioning at longer wavelengths enables imaging and detection of ‘lower energy phenomena’ that are not always observable in the visible and NIR ranges. When the noise from background VIS-SWIR solar radiation is removed, M/LWIR systems are capable of performing thermal imaging and thermography, detecting black-body radiation emitted by machines or organisms.

Objects radiating more heat – for example recently operated machinery or vehicle exhausts (100-500 °C) - emit radiation at shorter MWIR wavelengths (3-5 µm), as opposed to cooler, ‘room temperature’ (20-50 °C) objects such as inactive machinery or human beings emit radiation that is detectable in the LWIR (10-12 µm) range. This is according to Planck’s radiation law1 (see Equation 1):

|

Equation 1 |

where λ is the wavelength, T is the temperature, h is Planck’s constant, c is the speed of light, and k is Boltzmann’s constant.

Common applications of thermal imaging and thermography involve detection of radiation through the atmosphere – this is known as ‘stand-off’ detection and is taken at a specific distance from the object being imaged.

Scattering due to mist, fog, atmospheric, or gas molecules can impede this detection in the VIS/NIR/SWIR ranges, though for small particles such as these, this Rayleigh scattering is inversely exponentially dependent on the wavelength of the radiation being detected (λ-4).

One result of imaging in the MWIR and LWIR wavelength ranges is that it is not always possible to see through dust, mist, fog, and clouds. To selectively analyze particular thermal ranges, optical band-pass filters with very specific center wavelengths can be used in these systems, using a filter wheel to only view the area(s) of interest whilst simultaneously blocking out background signal which exists outside the desired area.

Specific molecular absorption bands exist within the M/LWIR that impede transmission. H2O displays a prominent absorption band between 6-8 µm, effectively creating an atmospheric ‘dead-zone’ between the MWIR and LWIR ranges.

While this water absorption band does restrict the useful range for thermal imaging and thermography, the narrow absorption peaks linked to other industrial and atmospheric gases have resulted in the detection and analysis of gas developing into a growing application area.

Two specific detection technologies have emerged which require unique optical filter characteristics. These are non-dispersive infrared (NDIR) gas detection and remote sensing which employs multi-spectral imaging (MSI).

NDIR Gas Detection

The detection and quantification of specific gas molecules is a useful tool in a wide range of markets and applications. These include:

- Flame detection

- Industrial process monitoring where the presence of a certain gas may be a key process parameter. For example, food spoilage or combustion (CH4, CO2, CO).

- Motion sensing and crowd populations

- Cabin air quality or automotive exhaust (NOx, CO2)

- Building air safety and quality (Formaldehyde, CO)

- Medical/health gas monitoring in sleep apnea, anesthesiology or breathalyzers

IR gas sensors provide an optical means of observing both the presence and concentration of these gas molecules. IR sensor systems do not rely on chemical reactions (unlike electrochemical sensors) so they are able to offer increased longevity with no performance degradation over time.

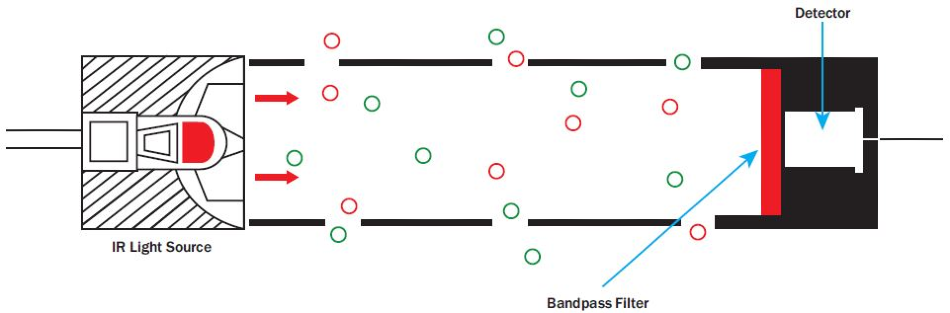

Non-dispersive infrared (NDIR) sensors are comparatively basic devices comprised of an IR light source and a gas sample volume, coupled with an IR detector.2 The central component in their functionality is a wavelength selective optical filter, located in front of the detector (Figure 1).

Figure 1. A nondispersive IR gas sensor is a simple device comprising an IR light source, a gas sample volume, and an IR detector.

IR light reaching the detector is absorbed according to the specific spectral ‘fingerprint’ of the species of gas molecule present (see Table 1). Using an optical filter with a band-pass region that corresponds to the peak absorption band of a specific gas (or gases) the intensity of filtered IR light reaching the detector will depend solely on the concentration of the gas in question.

Table 1. Mid- and long-wave infrared gas absorption peak wavelengths.

| Gas Molecule |

Peak Wavelength (µm) |

| H2O (Water) |

2.7 |

| CH4 (Methane and Other Hydrocarbons) |

~3.3 to 3.5 |

| CO2 (Carbon Dioxide) |

4.26 |

| CO (Carbon Monoxide) |

4.67 |

| NOx (Nitrogen Oxides) |

~5.3 |

| N2O (Nitrous Oxide) |

7.73 |

| O3 (Ozone) |

9.0 |

Should the chosen gas not be present then the intensity will match a reference level, while if the selected gas is present then the intensity at the detector will fluctuate with inverse proportionality to the concentration of gas, as per Lambert-Beer’s law (see Equation 2) where I is the intensity of light at the detector, Io is the reference intensity (no gas present), k is the absorption coefficient constant for the system, and P is the concentration of the specific gas being measured.

Optical filters used within these NDIR sensor systems are comparable to the narrow emission bandpass filters used within fluorescence detection and analysis, though these operate in the visible wavelength range.

Unfortunately, the conventional glass substrates and metal-oxide dielectric coating materials which are often used in the VIS range are no longer transparent when used in the M/LWIR.

There are many choices for suitably transparent substrates ideal for use in the M/LWIR - sapphire, ZnSe, Si, and Ge for example – though historically available coating materials in the M/LWIR were previously only able to be deposited by evaporation techniques, meaning that coatings were less durable.

Recent innovations in new sputtering methods have changed this, however. It is now possible to deposit IR transparent materials much more easily, allowing for the production of much more robust optical filters.

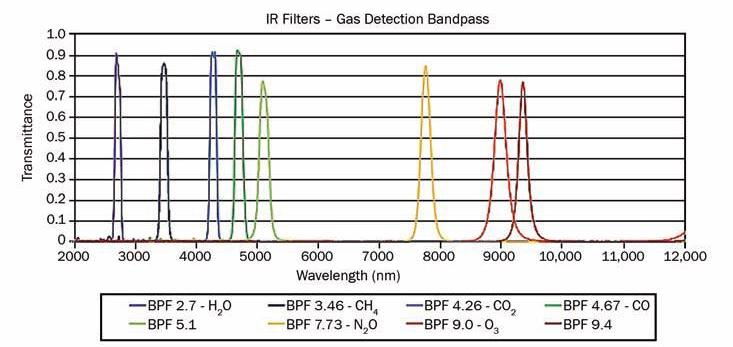

The implementation of these new, more durable sputtered materials allows coatings to be designed and deposited with narrow pass-bands (<5% of the center wavelength), high peak transmission (>70%), and broad blocking (UV-LWIR). All these options help to provide the high selectivity necessary for the detection of specific gas absorption lines.

Figure 2. Gas detection bandpass filter curves. New durable sputtered materials allow coatings to be designed and deposited with narrow passbands, offering high selectivity for the detection of specific gas absorption lines.

In the past, IR gas sensor systems were more expensive than electrochemical systems. However, the growing availability of low-cost MWIR sensors along with reduced costs, greater selectivity and enhanced durability in MWIR ‘gas band-pass’ optical filters has led to a marked increase in demand for NDIR gas sensors.

This is expected to continue with substantial future growth; growth which will continue due to the rise in sensor use throughout all aspects of society.

Remote Sensing and Multi-Spectral Imaging (MSI)

M/LWIR detectors have increased in affordability, but some applications still place a premium on optimizing detectors and systems to analyze multiple constituents and phenomena in one device.

Earth-observation instrumentation installed in satellites and used for the remote sensing of environmental characteristics should be optimized for size, space, and weight while keeping in mind budgetary constraints.

Additionally, the ability to combine the images of different time-varying phenomena to demonstrate dependencies and relationships between them is of particular value.

By coupling optical filters that offer spatially varying spectral performance (multi-zone filters) and a camera/detector; optical engineers have successfully produced multi-spectral imaging (MSI) systems. These systems are able to minimize payload size and cost, whilst providing ‘a snap-shot in time’ image fusion of several analytes at once.

Multispectral imaging systems designed for the VIS-NIR can be manufactured via photolithography processes, allowing for patterning of different spectral zones on a monolithic substrate. The coating thicknesses in the M/LWIR, in conjunction with different coating and substrate materials have posed challenges to this conventional means of MSI manufacture.

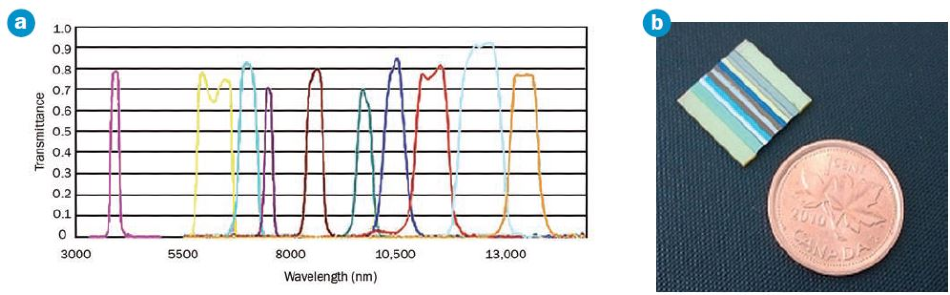

Iridian Spectral Technologies has provided a solution to this longstanding problem. It has developed technology to construct arrays from individual M/LWIR band-pass filters. Deposition processes and associated materials have been created to ensure robust spectrally selective individual filter elements which operate in a similar manner to the gas band-pass filters described earlier.

A great deal of experimentation has led to the development of assembly techniques that result in arrays that offer minimal pixel loss (due to well-controlled optical zone sizes and minimal transition zones) while comfortably meeting the required levels of reliability and durability for instruments intended to be deployed in space – for example, structural integrity, radiation insensitivity, etc.

The image below illustrates a recent example of the application of this technology. Developed under subcontract from ABB-Canada for the Space Technology Development Program (STDP) of the Canadian Space Agency (CSA), the optic below is comprised of ten different spectral bands in the M/LWIR, all housed in a footprint which is only the size of a penny.

Figure 3. Spectral curves (a) for the compact MWIR/LWIR filter array (b) developed under subcontract from ABB Canada for the Space Technology Development Program of the Canadian Space Agency.

The spectral bands in this optic permit simultaneous imaging of ozone levels, atmospheric ash, cloud height, wind and humidity levels, fires, fog, ice, and more.3 As this technology enters orbit, new capabilities for the measurement and monitoring of environmental characteristics in the Canadian arctic will help to enhance climatology and weather forecasting.

Leveraging M/LWIR multi-zone filters or using these alongside VIS-SWIR filters to provide even larger spectral coverage is also useful in a range of other remote sensing applications. These include areas such as forestry, agriculture, or the tracking of the impact of natural or man-made disasters - forest fires or volcanic ash clouds for example.

Conclusion

The capacity to image ‘invisible’ features like gases, thermal profiles, and other environmental constituents in a commercially viable way has led to a wide range of new application areas for M/LWIR sensor systems.

Developments in optical filter technology have opened this new wavelength window further with the future for photonics imaging in this wavelength area looking bright.

References and Further Reading

- Rogalski, K. Chrzanowski; Infrared devices and techniques; OPTO-ELECTRONICS REVIEW Rev.10, No. 2, 2002

- International Light Technologies; http://www.intl-lighttech.com/applications/lightsources/ndir-gas-sensor-lamps

- Alexander P. Trishchenko, Louis Garand; Canadian Polar Communication and Weather (PCW) satellite system: New capabilities for mapping Arctic snow and ice dynamics from Highly Elliptical Orbit

Acknowledgments

Produced from materials originally authored by Jason Palidwar from Iridian Spectral Technologies.

This information has been sourced, reviewed and adapted from materials provided by Iridian Spectral Technologies.

For more information on this source, please visit Iridian Spectral Technologies.