Clyde J. Coleman was awarded a patent for an electric automobile starter on the 24th of November, 1903. The 1912 Cadillac became the first car to replace the hand crank with an electric starter motor. Finally, by 1920, electric starter motors were fitted as standard across every model and brand of vehicle.

Hand cranks weren’t completely ideal, but they were accepted as the most appropriate solution because a better approach had not, at the time at least, been developed.

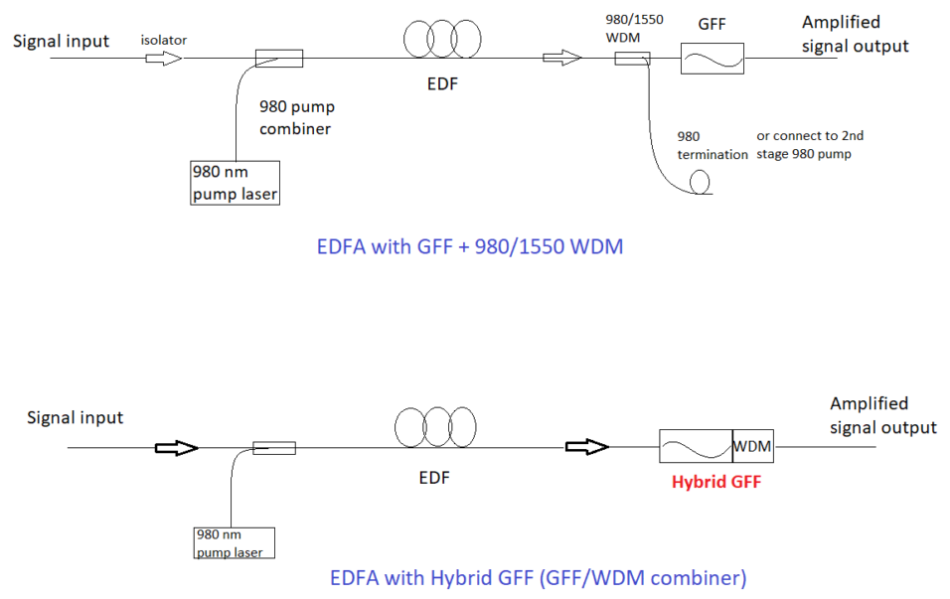

Similarly, using a gain flattening filter (GFF) alongside a wavelength-division multiplexer (WDM) in optical fiber amplifiers like erbium-doped fiber amplifiers (EDFA) has been considered the best approach, until the advent of the Hybrid GFF.

This article outlines what a Hybrid GFF is and how it functions. Additionally, it explores the benefits of using Iridian Spectral Technologies’ Hybrid GFFs instead of traditional two-filter setups in optical filter applications such as EDFA.

How GFFs and WDMs Serve Optical Fiber Amplifiers

Fiber optic communication systems often use EDFA modules to recover the optical signal following its transmission over a specific distance. Conventionally, this task was undertaken by electronic amplification by transferring the optical signal to an electrical signal before amplifying it, and then transferring that updated electrical signal back to an optical one.

EDFA modules (passive amplifiers), however, employ an erbium-doped fiber which removes the requirement to transfer signals from optical to electrical and then vice versa.

A laser with a wavelength of either 980 nm or 1480 nm is used to excite the erbium atoms. These then emit high numbers of photons when triggered by the far weaker incoming optical signal, at equal wavelengths to the incoming signal. This results in an amplified form of the input signal at the EDFA’s output, amplifying the optical signal in the process.

The majority of telecom wavelengths operate in the C-band (1520-1570 nm) or the L-band (1570-1620 nm). The pump laser will disrupt the specific wavelength of the signal it is working on – this obviously poses a problem in a fiber that accepts numerous communication channels.

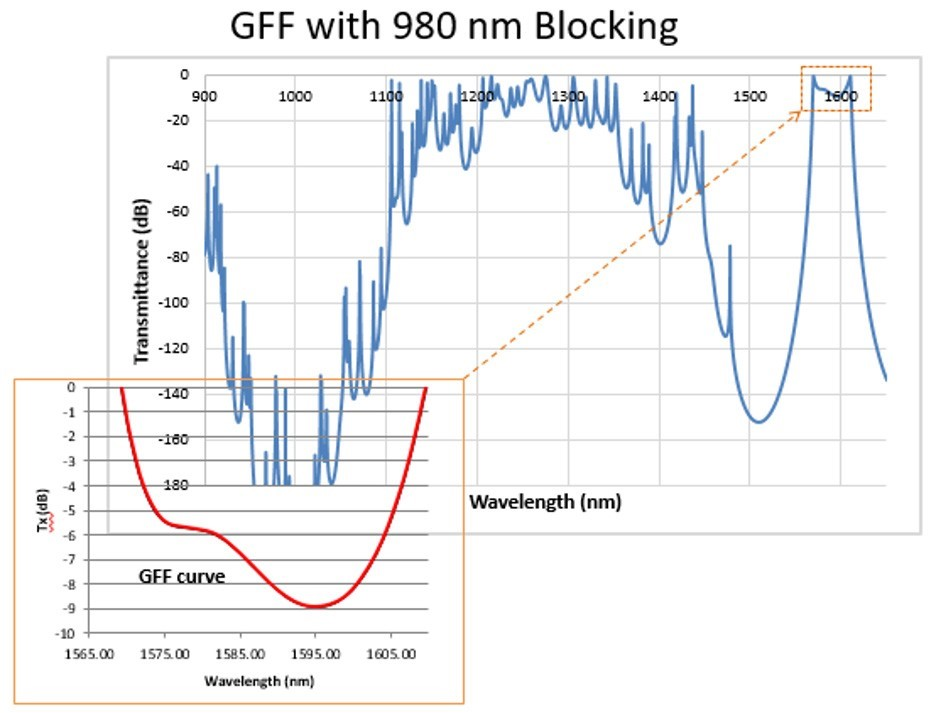

Conventional EDFA modules use two filter components to rectify the EDFA’s output signal. A GFF is used to ‘flatten’ - or level out - the outgoing amplified signal. This filter works alongside a 980 nm-blocking (or 1480 nm-blocking where applicable) wavelength-division multiplexer (WDM). The WDM is specifically used to reduce the interference caused by the pump laser.

What is a Hybrid Gain Flattening Filter, and What Advantages Does It Offer?

The Hybrid GFF has been developed by Iridian Spectral Technologies. This device merges the functionality of both the GFF and a WDM in a single unit. In particular, a Hybrid GFF is able to block the pump laser from light in the range of approximately 980 nm or 1480 nm while at the same time offering gain flattening for signal light amplification. When using a Hybrid GFF, there is no need for a separate pump wavelength blocking filter.

Additionally, a Hybrid GFF can be developed to block or pass a variety of wavelengths within the 900 nm to 1700 nm band.

It’s important to remember that both the GFF and WDM are complex, often expensive components from both a design and manufacturing point of view. Combining these units into a single component that is more cost-effective than two separate filters – while maintaining the same level of single-band or multiband performance – is quite the achievement.

The core benefit of Iridian’s Hybrid GFF is its significant cost savings; a Hybrid GFF does not cost much more than a base GFF, despite providing the functionality of the GFF and WDM.

Additionally, not requiring a separate WDM means one less component to consider, therefore reducing the complexity of system designs. This also means that overall, the dimensions of EDFAs and other optical amplifiers will be lessened, allowing for better use of available space or even a general reduction in equipment size.

Iridian’s Hybrid GFFs perform exceptionally well in terms of quantifiable performance metrics.

The performance of GFFs is most often defined by peak-to-peak error function (PPEF). Because Iridian is already established as a manufacturer of base GFFs that have exceptionally low PPEF, it has also ensured that its Hybrid GFFs possess this industry-leading capability.

It becomes more difficult to meet a customer’s desired PPEF with a base GFF as modulation depth deepens – that is, the greater gain variation that the component is needed to compensate for.

There is no compromise in performance when upgrading from a base GFF to a Hybrid GFF. In fact, when a Hybrid GFF is used, this provides a net performance gain over a two-filter setup because the insertion loss between the two filters is eliminated.

Iridian has contributed to the telecommunications industry for a long time, and as such, it understands that new system designs are able to take better advantage of Hybrid GFFs due to the qualification cycle required to successfully launch a new system or technology in the field.

To provide an example: a batch of EDFAs will be manufactured from a spool of fiber which has been doped with erbium. These draws of fiber have a certain gain profile, so a GFF will need to be designed to match that specific profile.

This filter specification will work as long as the same draw of fiber is being used. However, new draws of fiber will possess gain profiles that differ slightly, meaning that new GFFs will need to be designed and produced.

Because of these differences in gain, there is an opportunity for renovation every time optical amplifier components are updated. More specifically, each new round of GFFs (designed and manufactured to meet a target gain profile) provides an opportunity to implement system improvements and cost savings by employing Hybrid GFFs.

Utilize Iridian Spectral Technologies’ Expertise

Iridian’s capacity to develop Hybrid GFFs is a result of its experience creating optical filters for a diverse range of markets; from 3D cinema glasses and spectroscopy filters through to mid-wave infrared (IR) filters and space filters.

Because of the sheer range of experience (a result of working with other market areas and design approaches) available, Iridian’s design team possesses a much more thorough design and manufacturing toolbox than its competitors.

When a supplier only undertakes the same task or manufactures the same part all the time, their approach is not supplemented by other design philosophies, manufacturing strategies or opportunities.

Other industries saw the effectiveness of Toyota’s Total Productive Maintenance (TPM) approach, and this has now developed into the universally-used lean manufacturing philosophy. Iridian uses the same approach in its design for manufacture philosophy.

While a competent supplier should be able to design anything, it is important that a design is suitable for repeated manufacturing, often over increasing volumes, while ensuring high levels of quality or deliverability.

In order to address this issue, Iridian maintains a strict internal inspection and quality control program meaning that it can combine robust research and development with faultless gatekeeping.

Any uncertainties that need to be resolved are identified and addressed early, ensuring that every component shipped meets the highest standards. This is especially important early on in the implementation of a new technology.

Iridian’s proprietary software is also a key factor in ensuring this high quality. The coding is continually improved and developed in-house. This means that the same software is used for all design components controlling deposition equipment, establishing a feedback loop that ensures successful and repeatable results.

A final key factor which must be kept in mind is the nature of a strategic partnership. Commonly used and well-understood components rarely require room for innovation, so a traditional transactional supplier relationship is wholly appropriate in these cases.

However, Iridian is committed to building strategic supplier partnerships, encouraging customers’ requests to evolve beyond, “Build this optical filter, this way,” to “Here’s what my system does; how can you help?”

Conclusions

An Iridian Spectral Technologies Hybrid GFF lets system designers maximize capability, cost effectiveness and system simplicity simultaneously. Every company has different cost and performance requirements, so it is imperative that a prospective supplier has the technical knowledge base, experience and flexibility to adapt to the changing needs of existing systems and business structures.

Returning to the example cited earlier, in the same way that the electric car starter replaced the engine hand crank as the standard means of starting an engine, an improved option now exists for optical signal filtering that will redefine the approach to system design.

Acknowledgments

- Produced from materials originally authored by Xiaolun Zeng and Michelle Derouin from Iridian Spectral Technologies.

This information has been sourced, reviewed and adapted from materials provided by Iridian Spectral Technologies.

For more information on this source, please visit Iridian Spectral Technologies.