Mirror holders that are critically precise are utilized in the Geometry Scan Unit of Polytec’s Scanning Vibrometer. An automated machining center installed in Polytec’s production machine shop is where these holders are manufactured.

The machining can induce stresses in the part that can hinder the flatness of the mirror mounting surface. Deviations from the required flatness tolerances were discovered by utilizing a TopMap Topography Measurement System and were properly rectified during the manufacturing process.

Precision is the Key

The Geometry Scan Unit of the scanning vibrometer sensor head (image below) must aim the probe laser to the necessary measurement points utilizing software control to function properly.

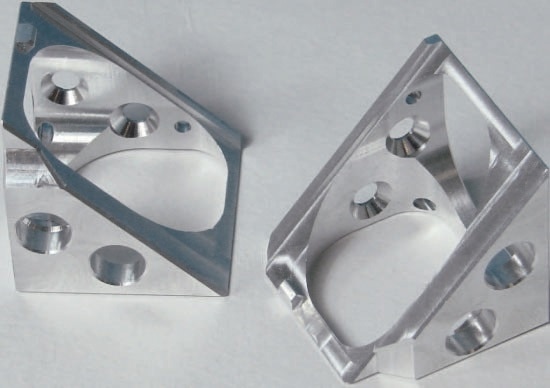

To hold the optic accurately, the mirror holders must be manufactured with high precision. Beginning with an aluminum rod, the outer surfaces, holes, and windows are turned and milled in a single run employing a CNC machining center.

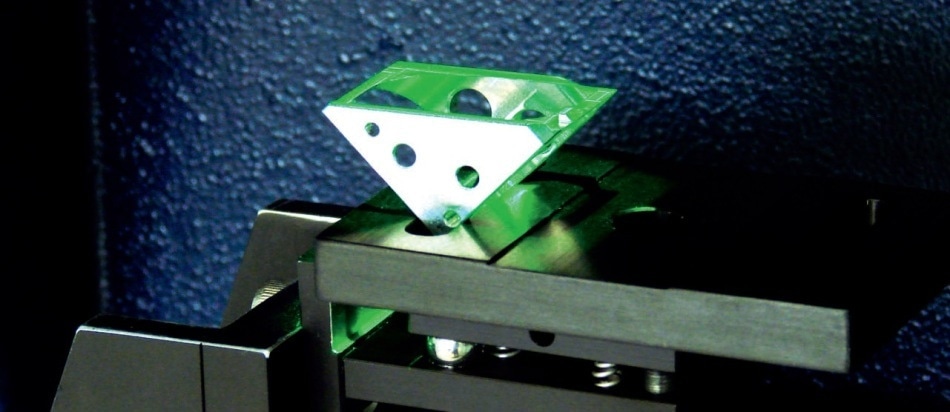

Figure 1. Mirror holder for the PSV geometry scan unit.

The mirror holder is an elaborate structure (detailed in Figure 1) with narrow portions that can distort and twist throughout the manufacturing process and afterward. Moving the mounting surfaces and misaligning the mirror are the effects of these distortions. The mirror will not work correctly and will be out of alignment if the flatness of the mounting surface falls under a critical value.

Flatness Measurements - Tactile or Optical

Containing relatively narrow and partially recessed ligaments; the mounting surface is highly intricate. It was impossible to establish the flatness with a traditional tactile sensor system as the scanner tip could only access a small portion of the surface.

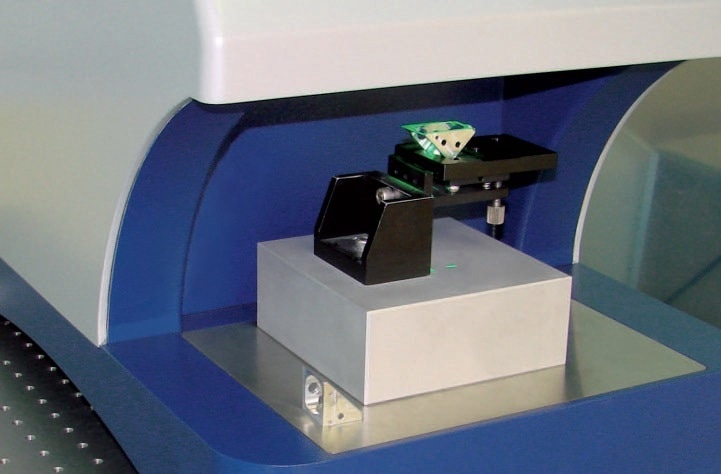

Figure 2. Measurement setup with TopMap Metro.Lab White-Light Interferometer.

This challenge was conveniently solved with the TopMap Topography Measurement System. The non-contact optical measurement technique enables the characterization of almost all surfaces, regardless of their particular geometric constraints.

The easy to use TMS-100 TopMap Metro.Lab was selected to establish the flatness of the mirror holder efficiently and with high accuracy (as demonstrated in Figure 2).

Results and Conclusions

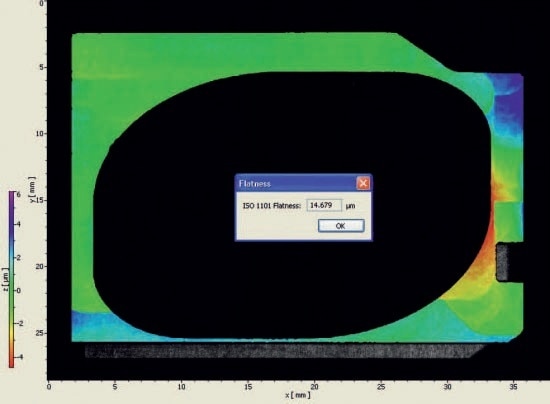

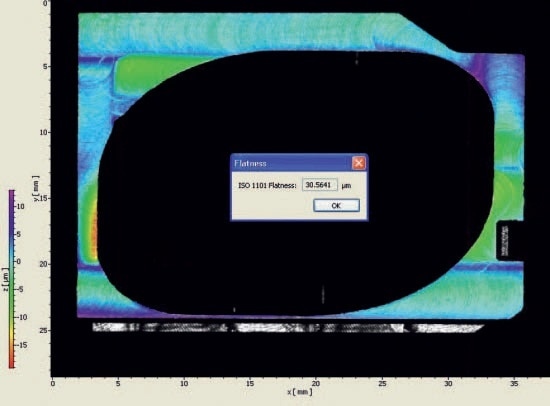

Figure 3. A good mirror holder shows a flatness measurement (<15 μm) that is within dimensional tolerances (ISO 1101).

Figure 4. A defective mirror holder shows a flatness measurement (>30 μm) that fails dimensional tolerances (ISO 1101).

Adhering to ISO 1101, the flatness of a good mirror holder (Figure 3) was compared to a defective mirror holder (Figure 4). The measurements demonstrate that deviations of up to 100% can happen. The flatness of the defective part is over 30 μm, whereas the good part has a flatness of around 15 μm.

It was possible to adjust the manufacturing process with the help of these measurements to decrease the stress creating the deformations. Without further steps being required, the manufactured parts now have the necessary flatness.

Therefore, when setting up the machining center, a prior examination of the workpieces utilizing the TopMap Metro.Lab can enable better quality control while saving both money and time.

The TopMap Metro.Lab is an ideal comparison standard for statistical process control in production runs, using random samples taken at scheduled intervals in batch processes to verify the consistency of the manufacturing process.

This creates much longer manufacturing intervals with continuous quality control. It is also possible to undertake serial measurement of workpieces on pallets. An investment in the Metro.Lab practically pays for itself in a short time due to TopMap’s good price to performance ratio.

More Information can be found at www.topmap.info.

More information about TopMap White-Light Interferometers can be found on the internet at www.topmap.info or the local Polytec sales or application engineer can be contacted.

This information has been sourced, reviewed and adapted from materials provided by Polytec.

For more information on this source, please visit Polytec.