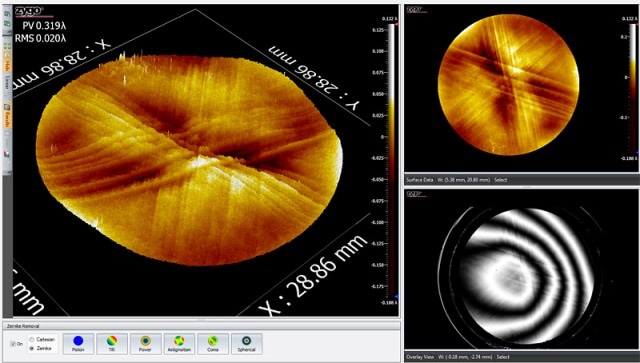

The Verifire™ HD interferometer system from ZYGO, provides transmitted wavefront measurement of optical components and assemblies, and fast high-resolution measurements of spherical or flat surfaces. The length of the interferometric cavity is accurately modulated as a high-speed camera captures numerous fringe images, which are evaluated by the software to make a highly detailed measurement of the part that is being tested.

Exposes Mid-Spatial Frequency

Surface Features

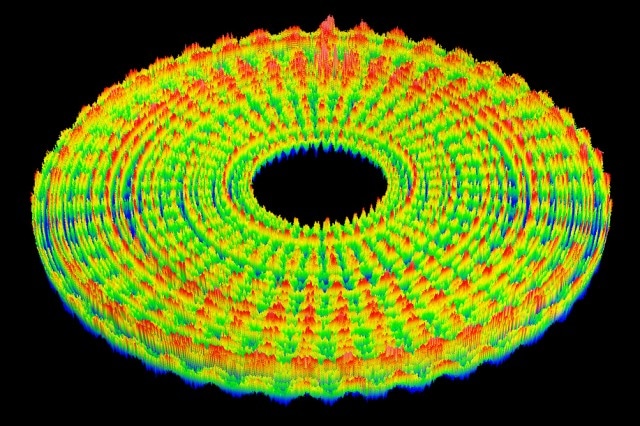

Mid-spatial frequency features can't hide any longer. The Verifire HD interferometer system boasts a high-resolution camera and improved optical design to consistently measure surface features that have been very challenging to determine in the past. In addition, the Mx™ software package provides the ability to measure the mid-spatial frequency content with Power Spectral Density (PSD) and the diffraction simulation tool.

Mid-spatial frequency chatter on a single point diamond turned optical surface

QPSI™ Vibration Tolerant Interferometry

The built-in QPSI technology removes ripple and phase noise produced by common sources of vibration, such as motors, pumps, grinding and polishing equipment, blowers, and personnel, which means customers can use the Verifire HD system on the production floor without the expense and hassle of vibration isolation tables.

The QPSI technology is enabled by a high frame rate camera and a powerful new proprietary laser. There is no need for special setup or calibration. A simple modification of a menu option enables/disables the QPSI technology.

Animated comparison of a PSI measurement with fringe print-through due to vibration, and the same surface measured with QPSI™ technology – free of noisy print-through.

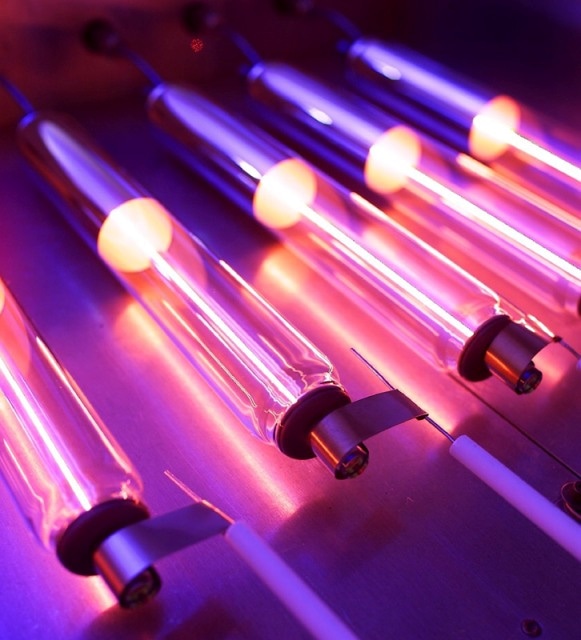

Powerful Long-Life Laser

The Verifire HD system’s unique performance capabilities require an equally unique laser, which had be more powerful compared to lasers that are typically found in interferometers, and have a much longer life span to reduce the inconvenience of downtime.

In order to ensure that the laser meets the exacting standards and stringent requirements, ZYGO decided to design and build it in-house. The company’s proprietary field-proven design offers unparalleled reliability and a much longer service life. This high-performance laser is exclusively available from ZYGO.

Proprietary long-life lasers are designed and manufactured by Zygo.

Modular Options, for Maximum Flexibility

The Verifire HD system is designed with multiple modular options so that it can be configured to suit the exact requirements of users. Some of the available configuration options include:

- 5.3 or 1.4 megapixel camera

- Point source or coherent noise reduction (artifact suppression)

- Fixed zoom, or discrete motorized turret zoom (1 x, 1.7 x, 3 x)

Mx™ Software

ZYGO's proprietary analysis software, Mx™, provides numerous operational features and data analysis tools for unparalleled measurement capability in a user-friendly interface. The integrated SPC offers powerful capability for production environment.

How it Works

The Verifire™ HD interferometer system uses the accuracy of mechanical phase modulation in order to demonstrate fine measurement detail on optical surfaces with outstanding precision and repeatability. The length of the interferometric cavity is precisely modulated during a measurement as a high-speed 2 k x 2 k pixel CCD camera captures numerous fringe images, which are evaluated by the software to make a highly detailed measurement of the part that is being tested.

Verifire™ HD system is ideal for measurements of glass or plastic optical components such as lenses, prisms, and flats, precision metal components such as bearing and sealing surfaces, and computer disks, as well as contact lens molds and polished ceramics.

Interferometer measuring in vibration performs metrology with noise-free interferometry data