Oct 5 2022Reviewed by Alex Smith

Researchers have demonstrated that a complicated, high-quality polymer optical device can be created using 3D laser printing right on the end of an optical fiber. This type of micro-optical system, which contains components with details smaller than the diameter of a human hair, can offer a remarkably small and reasonably priced method of modifying light beams for different applications.

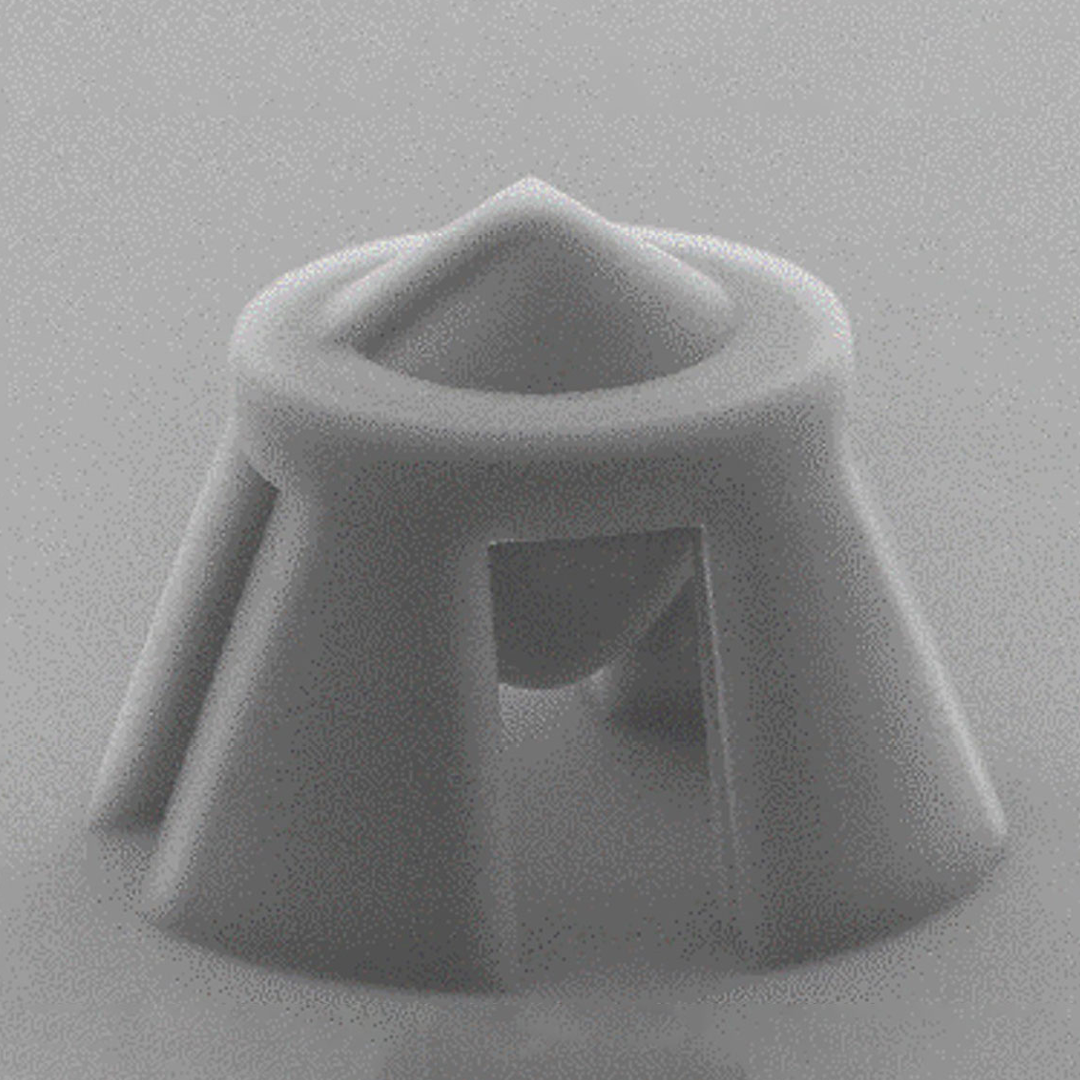

Researchers used 3D laser printing to fabricate a high-quality, complex polymer optical device directly on the end of an optical fiber. A scanning electron microscopy image of the device is shown. It includes both a parabolic lens for light collimation and a twisted axicon optic that twists the light. Image Credit: Shlomi Litman, Soreq Nuclear Research Center

Researchers used 3D laser printing to fabricate a high-quality, complex polymer optical device directly on the end of an optical fiber. A scanning electron microscopy image of the device is shown. It includes both a parabolic lens for light collimation and a twisted axicon optic that twists the light. Image Credit: Shlomi Litman, Soreq Nuclear Research Center

Communication technologies, the internet, and many other applications are based on optical fibers.

Shlomi Lightman, Research Team Leader, Soreq Nuclear Research Center

Lightman added, “When light comes out of the fiber, large bulky optical elements are typically used to route it to the next location. Our approach minimizes both the size and cost for this process by integrating the routing process into the fiber itself.”

Lightman and colleagues describe how they built the tiny multi-component beam shaper right onto a fiber in the Optics Letters journal from the Optica Publishing Group. Normal laser light is converted into a twisted Bessel beam by the device, which has orbital angular momentum and does not extend in space as other light beams do.

In less than five minutes, the researchers constructed the full micro-optical device. The cost of the fiber and micro-optical device combination was less than $100, or roughly one-tenth the price of a typical microscope objective lens that serves a similar purpose.

“The ability to create a Bessel beam directly from an optical fiber could be used for particle manipulation or fiber-integrated stimulated emission depletion (STED) microscopy, a technique that produces super-resolution images. Our fabrication method could also be used to upgrade an inexpensive lens to a higher quality smart lens by printing a smart small structure on it,” Lightman further stated.

Precision Planning

The researchers employed 3D direct laser printing, a fabrication method, to create the small optical components. Two-photon absorption is produced in a photosensitive optical medium using femtosecond laser pulses. High-resolution 3D elements can be produced because only the minuscule volumes, where two-photon absorption takes place, solidify.

Even though 3D direct laser printing has been around for a while, it can be challenging to fabricate such tiny optics on a fiber tip with the proper size and alignment.

Lightman stated, “We were able to overcome this hurdle by performing highly accurate 2D and 3D simulations before we began the fabrication process. In addition, we had to carefully think about how to integrate the optical elements with each other and then align that with the fiber core.”

The researchers used a commercial 3D direct laser writing technology and a high optical quality photosensitive polymer to print an optical device that was 110 microns tall and 60 microns wide on the end of a single mode optical fiber after careful planning based on the simulations.

Both a helical axicon lens and a parabolic lens for collimating light were present in the apparatus. This causes the beam of light that leaves the fiber to become twisted.

High-Quality Light Propagation

The researchers constructed an optical measurement system to record the shaped beam traveling from the modified fiber to evaluate the fabrication quality of the optical device. The beam had very little diffraction, which suggests that it might be useful for tasks like particle manipulation and STED microscopy.

Furthermore, they discovered that the laser power might approach 10 MW/cm2 without harming the manufactured micro-optical device. This demonstrated that relatively high laser power could be produced even though the device was built of polymer, which is more vulnerable to heat damage from high powers than glass.

The researchers are exploring hybrid photosensitive materials that have a low percentage of polymer now that they have shown that precise multi-element micro-optics can be produced using this direct 3D laser printing technique.

In comparison to polymer materials, these materials can enable the production of higher-quality optics that also have a longer shelf life and are more resistant to powerful lasers.

Journal Reference:

Lightman, S., et al. (2022) Vortex-Bessel beam generation by 3D direct printing of an integrated multi-optical element on a fiber tip. Optics Letters. doi:10.1364/OL.470924.

Source: https://www.optica.org/en-us/home/