A newly invented device uses laser light to monitor gas pressure. The technology, created at Umeå University and the Industrial Doctoral School for Research and Innovation, provides incredibly exact readings and could, for example, identify extremely minor gas leaks quickly.

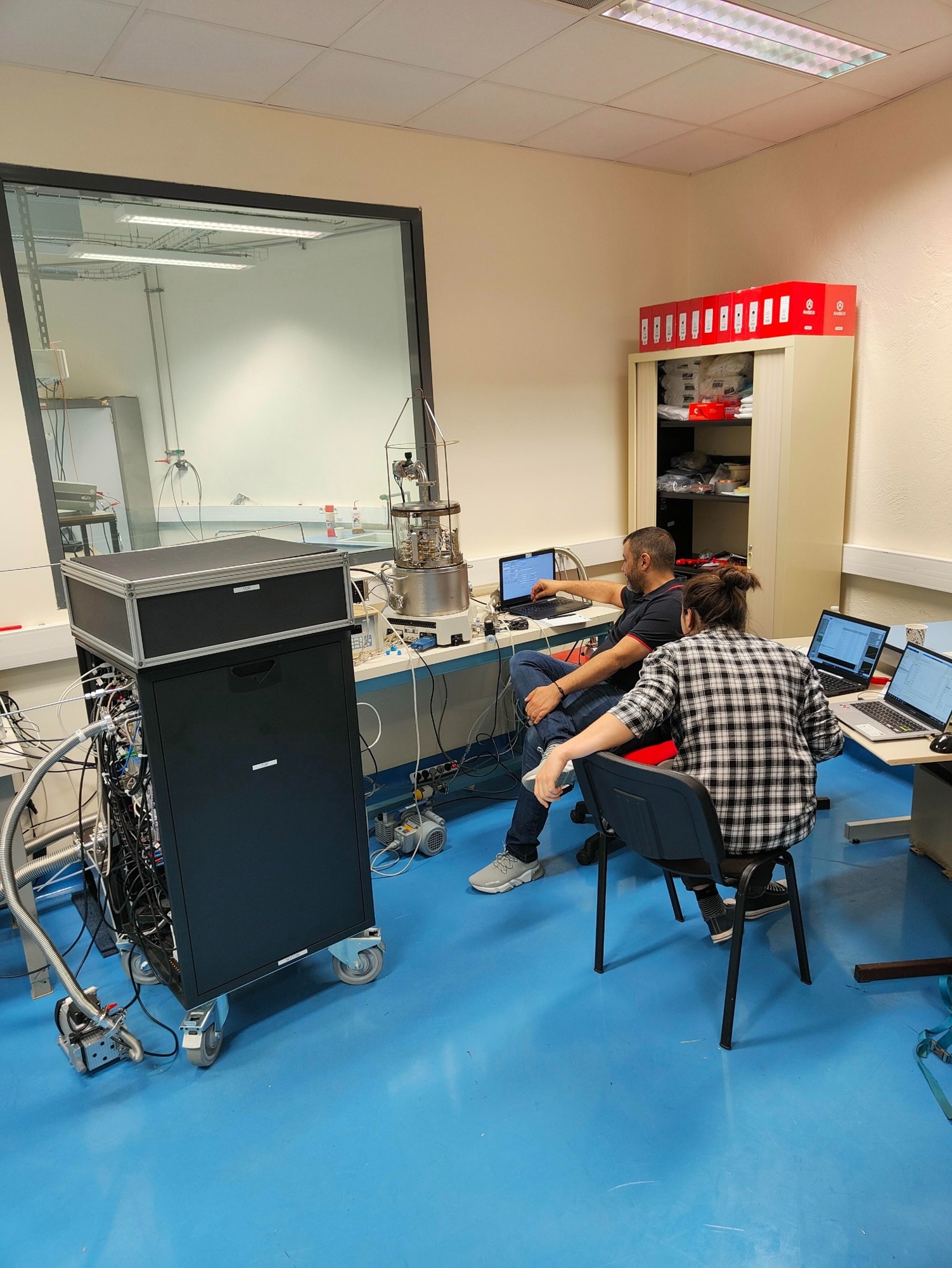

Clayton Forssén visited the National Metrology Institute in Paris during his work. The picture shows a conventional pressure standard in the middle, the current realization of the SI unit for pressure. On the left is the portable instrument built by Clayton Forssén. Image Credit: Zaccaria Silvestri

The ability to define and recognize SI units—such as the meter, second, and kilogram—with high precision is becoming increasingly vital in the modern world. What one meter is or how much one kilogram weighs is something that is taken for granted, but it is constantly monitored and developed by national metrology institutions across the world.

One of their responsibilities is to ensure the quality of the measuring equipment so that people can buy groceries, refill their cars, and set up their watches with confidence.

Clayton Forssén, a Ph.D. student at the Industrial Doctoral School for Research and Innovation, provides a novel means of identifying the SI unit of pressure, the Pascal, that is both exact and accessible in his doctoral thesis. The study was carried out in partnership with the Swedish National Metrology Institute, which is housed within RI:SE Research Institutes of Sweden.

Contributing to Safer Workplaces

Unlike the traditional method of realizing pressure by applying a known force on a known area, the new method is based on Boltzmann’s constant and an exceptionally accurate laser measurement of gas density.

Clayton Forssén, Ph.D. Student, Industrial Doctoral School for Research and Innovation, Umeå University

The new instrument allows for a more exact worldwide definition of pressure as well as the creation of future solutions in fields such as healthcare, industry, and research where precise and accurate pressure is required. Some uses include the precise administering of drugs in medical applications and the handling of hazardous gases in industry.

Extremely minute gas leaks can be detected in real-time with the new equipment, contributing to enhanced safety when working with explosive or hazardous gases.

Sensitive Instruments

This equipment is frequently delicate, making them difficult to transport outside of the lab. Clayton Forssén, on the other hand, has succeeded in developing a portable device that can detect pressure with great precision even outside of well-controlled surroundings. This allows the technology to be introduced into society and benefit additional applications.

Forssén added, “Applying a realization for pressure directly can eliminate the need for calibrations, which is very costly but above all carries a high price for the environment. Working with experts on realizations for the SI units across Europe has been incredibly rewarding. I’ve seen how much work goes into developing and quality assuring these devices, all with the aim of minimizing the impact on us as individuals in society. Being able to contribute to this work that is focused on improving the future of the global community is, of course, something I take great pride in.”

Source: https://www.umu.se/en/