Aug 10 2017

An optical analysis method formulated, for the first time, by a team of Researchers can reveal weak areas in ceramic thermal barrier coatings that shield jet engine turbines from wear and high temperatures.

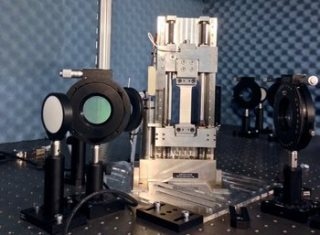

Researchers used a tensile machine to pull a metal specimen with a ceramic thermal barrier coating sprayed on its surface. With a polariscope, they could measure changes in refractive index resulting from this applied strain. Some of the components of the GHz polariscope are seen on either side of the tensile machine. (Image Credit: Peter J. Schemmel, Heriot-Watt University)

Researchers used a tensile machine to pull a metal specimen with a ceramic thermal barrier coating sprayed on its surface. With a polariscope, they could measure changes in refractive index resulting from this applied strain. Some of the components of the GHz polariscope are seen on either side of the tensile machine. (Image Credit: Peter J. Schemmel, Heriot-Watt University)

The method could be used to calculate how long coatings would last on an airplane and might in time lead to new thermal barrier coatings, making engines more efficient and reducing both the pollution and cost of air travel.

The service life of a thermal barrier coating applied on airplane turbine blades can range extensively from 1,000 hours up to 10,000 hours at full turbine thrust, even when the coating is applied in the exact same manner. As the service life is random and failure during flight could be disastrous, turbine blades are slated for replacement established on the shortest estimated lifetime.

Our strain-measurement technique can analyze the coatings immediately after manufacturing and work to identify the turbine blades that would last the longest in the airplane. Ultimately, we want to develop an imaging device that would show the strain distribution in the coating of an entire turbine blade, information that would be used to decide if that turbine blade would go into service.

Andrew J. Moore, Leader of the Research Team, Heriot-Watt University, UK

In The Optical Society journal Optics Express, the Researchers showed that changes in refractive index, a measure of how quickly light travels through a material, could be seen when a piece of metal coated with a ceramic thermal barrier coating was pulled in a controlled manner. Moore’s research team is working together with Rolls-Royce, a leading manufacturer of jet engines.

If we can correlate how the strain distribution is related to the coating’s lifetime, then we could determine which coatings will fail first and shouldn’t be put into an aircraft and which ones will last much longer. This would increase the time between services significantly, which would bring huge savings.

Andrew J. Moore, Leader of the Research Team, Heriot-Watt University, UK

The new method could also be used to predict the lifetimes of coatings created to tolerate higher temperatures or to be more reliable, which allows engines to function more efficiently. It might also find application in nuclear power and automotive applications where ceramics are also used as thermal barriers.

Seeing through opaque materials

Using gigahertz (GHz) illumination was crucial to the new method because these wavelengths can pass though certain opaque materials, such as ceramics, enabling analysis to be done from within the material. On the other hand, visible wavelengths can only be used for surface examination of opaque materials.

The team tested their method with pieces of metal sprayed with the same ceramic coatings applied on Rolls Royce turbine blades. They placed the pieces into a tensile machine that applied strain by gradually pulling the metal. Then they applied GHz illumination (280-380 GHz) during the process, which traveled via the ceramic coating and bounced off the metal underneath.

The reflected light was then measured using a polariscope to establish how the refractive index of the ceramic altered with the applied strain. Although the team’s present optical setup only obtains point-based measurements, the Researchers say the method could be applied with an imaging setup to examine an entire blade.

With the GHz illumination we were able to see changes in the refractive index with applied strain. This shows that our approach could be applied for quality assurance in the future.

Andrew J. Moore, Leader of the Research Team, Heriot-Watt University, UK

The Researchers now started experimenting with higher frequency illumination in the terahertz (THz) range, which could enhance the method’s spatial resolution. In partnership with Cranfield University, UK, they are also using their method to make strain measurements of ceramic-coated metal samples that experience accelerated aging. “We will be looking to see when the coatings fail and then correlating that with GHz and THz measurements we took prior to the aging process,” said Moore. “This is a step toward using our technique to identify which coatings fail first.”