Oct 17 2016

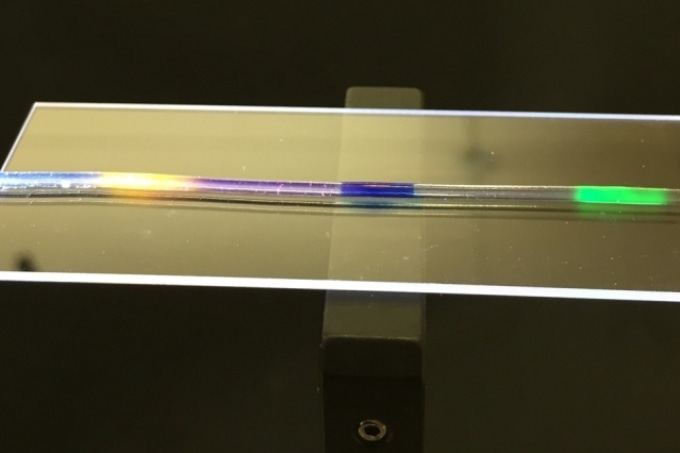

MIT researchers have developed a stretchy optical fiber in which they have injected multiple organic dyes (yellow, blue, and green regions). In addition to lighting up, the dyes act as a strain sensor, enabling researchers to quantify where and by how much a fiber has been stretched. (Courtesy of the researchers)

MIT researchers have developed a stretchy optical fiber in which they have injected multiple organic dyes (yellow, blue, and green regions). In addition to lighting up, the dyes act as a strain sensor, enabling researchers to quantify where and by how much a fiber has been stretched. (Courtesy of the researchers)

A collaborative team of researchers from MIT and Harvard Medical School have produced a biocompatible and highly stretchable optical fiber made from hydrogel. Hydrogel is an elastic, rubbery material consisting mostly of water. The fiber, which is as bendable as a string of licorice, could potentially be implanted in the body to convey therapeutic pulses of light or to light up when the first sign of disease is detected.

The team say that the fiber could be used as an enduring implant that would twist and bend with the body without deforming. The results of their research have been published online in the Advanced Materials.

Using light to trigger cells, and specifically neurons in the brain, is a highly active field known as optogenetics, where researchers deliver short pulses of light to targeted tissues using needle-like fibers, via which they shine light from an LED source.

But the brain is like a bowl of Jell-O, whereas these fibers are like glass — very rigid, which can possibly damage brain tissues. If these fibers could match the flexibility and softness of the brain, they could provide long-term more effective stimulation and therapy.

Xuanhe Zhao, the Robert N. Noyce Career Development Associate Professor, MIT

Getting to the Core of it

Zhao’s group at MIT, including graduate students Xinyue Liu and Hyunwoo Yuk, specializes in tweaking the mechanical properties of hydrogels. The team have devised several recipes for creating tough yet flexible hydrogels using a number of biopolymers. The team has also prepared many methods to bond hydrogels with various surfaces such as LEDs and metallic sensors, to develop stretchable electronics.

The researchers came up with an idea to investigate hydrogel’s application in optical fibers after talks with the bio-optics group at Harvard Medical School, headed by Associate Professor Seok-Hyun (Andy) Yun.

Yun’s team had earlier fabricated an optical fiber using hydrogel material that successfully conveyed light via the fiber. However, the material deformed when bent or stretched a little. In contrast, Zhao’s hydrogels could stretch and bend in the same manner as taffy. The two teams combined their efforts and explored ways to integrate Zhao’s hydrogel into Yun’s optical fiber design.

Yun’s design comprises of a core material enclosed in an outer cladding. To convey the maximum quantity of light via the core of the fiber, the core and the cladding has to be built using materials with highly different refractive indices, or degrees to which light can be bent by it.

If these two things are too similar, whatever light source flows through the fiber will just fade away. In optical fibers, people want to have a much higher refractive index in the core, versus cladding, so that when light goes through the core, it bounces off the interface of the cladding and stays within the core.

Hyunwoo Yuk, Graduate Student, MIT

They discovered that hydrogel material created by Zhao was very transparent and had a refractive index that was perfect as a core material. However, when they coated the hydrogel with a cladding polymer solution, the two materials peeled apart when the fiber was bent or stretched.

Aiming to bond the two materials together, the team combined conjugation chemicals with the cladding solution, which, when coated over the hydrogel core, produced chemical links between the outer surfaces of both materials.

“It clicks together the carboxyl groups in the cladding, and the amine groups in the core material, like molecular-level glue,” Yuk says.

Sensing Strain

The researchers studied the ability of the optical fibers to propagate light by shining a laser via fibers of varying lengths. Each fiber conveyed light without much attenuation or fading. They also discovered that it was now possible to stretch the fibers more than seven times their initial length without breaking.

With the newly developed extremely flexible and strong optical fiber, created from a hydrogel material that was also biocompatible, the team started to analyze the fiber’s optical properties, to see if it was possible to design a fiber that could sense where and when it was stretched.

They initially loaded a fiber with red, blue and green organic dyes, placed at particular spots along the length of the fiber. Then, they shone a laser via the fiber and stretched, for example, the red region. They measured the light spectrum that occurred all of the way through the fiber, and made note of the intensity of the red light.

They rationalized that this intensity links directly to the quantity of light absorbed by the red dye, due to that region being stretched. Simply put, by calculating the quantity of light at the far end of the fiber, the team can quantitatively conclude by how much and where a fiber was stretched.

“When you stretch a certain portion of the fiber, the dimensions of that part of the fiber changes, along with the amount of light that region absorbs and scatters, so in this way, the fiber can serve as a sensor of strain,” Liu explains.

This is like a multistrain sensor through a single fiber. So it can be an implantable or wearable strain gauge.

Hyunwoo Yuk, Graduate Student, MIT

The researchers envision that such stretchable, strain-sensing optical fibers could be fitted or implanted along the length of a patient’s leg or arm, to examine for signs of improving mobility. Zhao imagines that the fibers may also be used as sensors, lighting up in reaction to signs of disease.

“We may be able to use optical fibers for long-term diagnostics, to optically monitor tumors or inflammation,” he says. “The applications can be impactful.”

“Hydrogel fibers are very interesting and provide a compelling direction for embedding light within the human body,” says Fiorenzo Omenetto, a professor of biological engineering at Tufts University, who was not involved in the work. “These efforts in optimizing and managing the physical and mechanical properties of fibers are necessary and important next steps that will enable practical applications of medical relevance.”

This research work was supported, partially, by the National Institutes of Health, and the Department of Defense.