Jan 31 2012

Market leaders in temperature controlled microscopy, Linkam Scientific Instruments report on the use of their THMS600 temperature stage as part of a system from Biopharma Technology Limited (BTL) to characterize freeze drying processes at the University of Iowa.

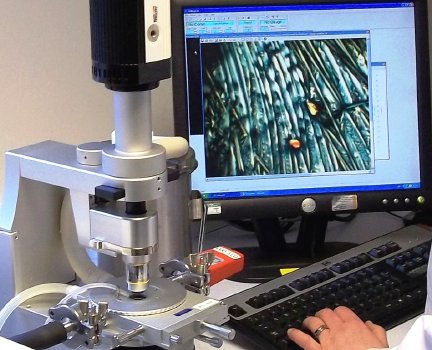

The Lyostat 2 system incorporating the Linkam cryo stage, THMS 600, is used at UIP (University of Iowa Pharmaceuticals).

The Lyostat 2 system incorporating the Linkam cryo stage, THMS 600, is used at UIP (University of Iowa Pharmaceuticals).

The University of Iowa Pharmaceuticals (UIP) is the largest and most experienced university-affiliated FDA-registered pharmaceutical manufacturing facility in the United States. UIP has been developing formulations, manufacturing products, and conducting analytical testing in compliance with current Good Manufacturing Practices (cGMPs) for over 30 years. The facility is the only one of its kind offering the range and scope of services needed by commercial clients. Additionally, UIP has performed work for numerous government agencies, including the National Cancer Institute, the Centers for Disease Control, the World Health Organization, the National Institutes of Health, and the Food and Drug Administration.

One area of interest is the understanding of lyophilisation processes. Key to this is the characterization instrumentation from Biopharma Technology Limited. Two systems are in use: The Lyotherm 2 provides integrated Differential Thermal Analyser (DTA) and electrical impedance (Zsinö) capability in a single instrument. The Lyotherm 2 is designed to measure glass transition (Tg'), eutectic (Teu) and melting (Tm) temperatures relevant to freeze-drying formulations. The Lyostat 2 is a fully integrated freeze-drying microscope which incorporates a Linkam THMS 600 cryo temperature stage. This enables critical events such as collapse and melting to be observed in situ, as well as characteristics such as skin or crust formation to be observed and identified. The coupled Lyostat 2 and Lyotherm 2 units provide valuable information for both formulation and cycle development processes. With UIP's in-house expertise in lyophilization, this combination will allow quicker and more efficient development of lyophilization cycles.

The team is led by Professor Lee Kirsch of the College of Pharmacy. His research interests include macromolecular peptide pro-drugs for targeted drug delivery, the kinetics and mechanisms of the chemical instability of drugs, the kinetics and mechanisms of the physical instability of dispersed and colloidal systems, and pharmaceutical package integrity technologies. One of his team describes the main work with the Lyostat 2 system. "We use the system to find out the collapse temperature for various clients freeze drying formulations." Until the arrival of the Lyostat 2, determining the collapse temperature would take hours in the lab in an attempt to understand the critical temperatures needed to produce the best product. The ability to provide accurate thermal characterisation right down to -196°C significantly reduced the time and complexity in the process enabling scientists to determine these key temperatures and so create the best product quickly and simply.

The collaboration between BTL and Linkam has enabled a practical solution to questions on freeze drying previously only answered with difficulty. Adding the temperature stage has brought benefits to BTL through being able to provide quality pictures to illustrate the process at varying precisely controlled temperatures and pressures while, for Linkam, it has introduced the company to an exciting and growing market.