A large part of Photonic Science’s focus is on Laue cameras. Initially, Photonic Science began selling these systems and cameras for scientific purposes but has since moved onto selling these systems for more industrial purposes. Each Laue camera system is built to purpose, unlike old-fashioned and expensive diffraction systems. Overall, Photonic Science has more than 200 systems in the field in operation.

Laue cameras use a technique that utilizes back-reflection geometry. There is a polychromatic, low energy X-ray beam that goes through a detector and a sample on the other side of the detector, which reflects the X-ray beam and forms a set of diffraction spots. These diffraction spots are then recorded directly onto the detector.

The indexation of the diffraction pattern is specific for each crystal orientation and allows materials scientists and physicists to grow and then cut crystals with electro-optical properties.

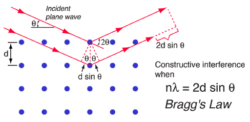

What is Laue Diffraction?

The physics that facilitates a Laue camera’s function include X-rays that interact with electron clouds on a single crystal or an alloy. The reflected beam is recorded onto the Laue detector if it satisfies Bragg’s law, which is when the incident angle of an X-ray beam is such that the difference in X-ray path lengths between crystal planes is an integer number of wavelengths so that constructive interference occurs, which makes a diffracted beam. It is a relatively simple equation, which allows scientists to locate the spots according to a specific orientation of a crystal.

Laue Spots Sapphire Sample C-axis aligned.

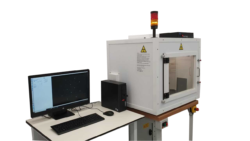

The components in a Laue system include high brightness, microfocus X-ray source, a low noise, large area X-ray detector, and a manual or motorized stage onto which the sample is positioned.

In the past, two-kilowatt X-ray sources have been used in Laue cameras, which required complex cooling and power-hungry installations. Now, 25 W of effective power is used.

Photonic Science’s Laue camera system has a much smaller X-ray beam footprint delivered onto the sample, and the system can handle sub-millimeter range samples. Combined with a large area, high-resolution detector, it is possible to achieve orientation accuracy down to 0.05 degrees. The system geometry can accommodate wafers, large ingots as well as larger components such as turbine alloys.

Acquiring a Laue Diffraction Pattern

To measure a mis-cut angle from a crystallographic orientation down to < 0.1-degree accuracy, for example, acquiring a Laue diffraction pattern would be achieved by overlaying a theoretical pattern onto an experimental one and recording the deviation from the theoretical spot position.

The Bragg equation would allow for the derivation of the exact misorientation over three angular axes of the crystal lattice using Photonic Science’s dedicated Laue software.

PSEL dedicated Laue software.

How Photonic Science Laue Cameras Stand Out in the Market

As the X-ray beam footprint is a lot smaller in Photonic Science’s Laue cameras, material scientists and physicists benefit from being able to identify sub-grain structures and orientation. The Photonic Science system can also acquire up to 10,000 orientation measurements automatically on large polycrystalline samples, such as solar cells, which helps in the understanding of the effect of grain orientation versus cell efficiency.

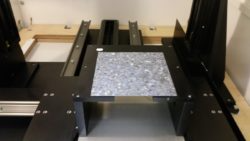

Vertical Laue system.

Photonic Science’s Laue systems can also be highly customizable according to the customer’s environment and requirements. Typically, Photonic Science provides a turn-key solution, sample holders, goniometers, and scanning stages to align crystals on a routinely basis prior to transfer to a suitable cutting tool.

Polycrystalline Silicon Wafer Scanner.

Detector materials such as CdTe, GaAs, microelectronic substrates such as GaN, and piezo materials cut and diced as wafers are subject to automatic batch testing, and Photonic Science offer sample holders hosting up to 100 samples, which are scanned using a single press button procedure.

Laser materials or Sapphire comes in large-bulk, heavy-duty stages, which are then used to accommodate samples from 10 up to >100 kg. Thin-film orientations such as AlN are also controlled using the finest precision stages with multi-point scanning routine.

Laue Crystal Orientation System.

To find out more about Photonic Science’s Laue camera systems, contact a member of the Photonic Science team.

This information has been sourced, reviewed and adapted from materials provided by Photonic Science.

For more information on this source, please visit Photonic Science.