Jun 8 2017

From smartphones to laptops and TVs, light emitting diode (LED) displays are present everywhere. Among these devices, OLEDs (where the O signifies they are organic or carbon-based) are the most energy efficient; however, they commonly have higher production costs due to the difficult fabrication processes required to arrange them properly.

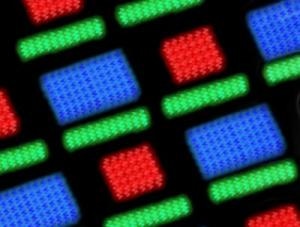

Organic light emitting diode (OLED) arrays generated in solution can overcome many fabrication challenges. Credit: Zak Page

Organic light emitting diode (OLED) arrays generated in solution can overcome many fabrication challenges. Credit: Zak Page

Today, Researchers have introduced a new method to efficiently create patterns of OLEDs in ACS Central Science.

In an LED display, the emissions generated by red, green and blue diodes are combined to create the white and colored light needed to render images. It is very important to position the different types of diodes correctly in relation to one another. Although numerous fabrication methods are currently available, they all have limitations regarding feature resolution, pattern control or scalability. Solution-based protocols are very attractive because they are inexpensive and suitable for large-scale manufacturing. However, current methods fail to meet the demands needed for commercial OLED display technology. Craig Hawker, Zak Page and collaborators at the Dow Chemical Company and the University of California, Santa Barbara wanted to overcome this obstacle by adopting a bottom-up method for patterning emissive polymers.

Beginning with a substrate of indium tin oxide, the Investigators used light-activated chemistry in order to identify particular locations on the surface for polymer growth. Designer iridium photocatalysts are key to the success of this method. At first, these photocatalysts can serve as the catalyst to make the emissive brush polymers, and then as a necessary dopant for the resulting OLED arrays. The Authors revealed the feasibility of their system by fabricating functional multi-colored OLED arrays, and they note that their method may allow high throughput manufacturing of OLEDs with different technologies, including inkjet printing in the future.