Feb 9 2017

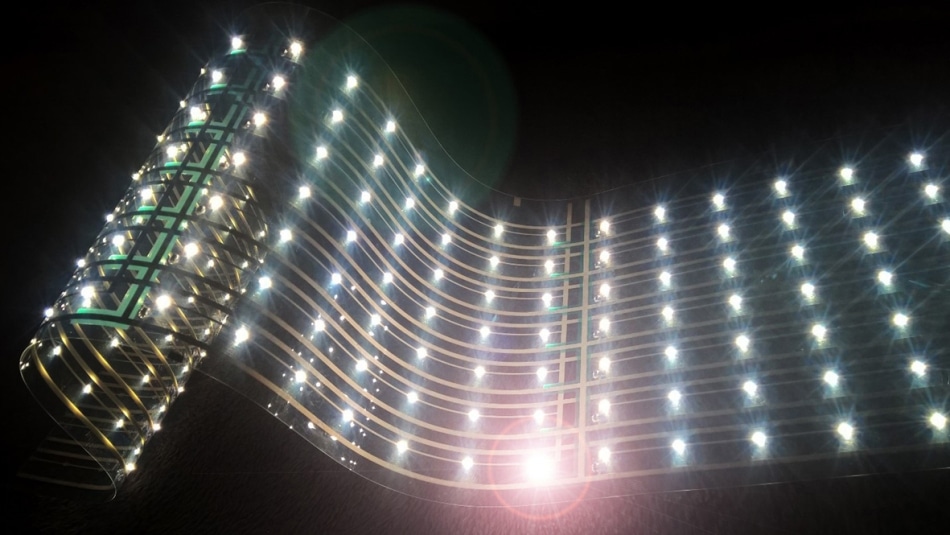

VTT Technical Research Centre of Finland in partnership with the Finnish companies Flexbright and Lighting Design Collective is developing new LED light sources based on large, transparent, and flexible substrates.

Photo credit: Flexbright

Photo credit: Flexbright

An LED foil, which is easy to customize and suitable for large scale production, enables the use of the large area lighting and display technologies in applications such as vehicles, shopping centers, greenhouses, and architectural lighting.

Delphi4LED, a three-year European project, creates design and simulation tools for LED structures to ideally match the requirements of the quickly evolving lighting industry and customers.

Heat management is a crucial factor influencing the reliability and performance of LED lighting solutions. Optical and electrical properties of the LED components also influence the operation of LED components. Incorporating all of these properties is tough using the design tools that are currently available.

New simulation models are being created in the Delphi4LED project in order to consider the factors mentioned above in a simplified form. This saves on computing capacity, facilitating a more detailed design than is presently possible.

Detailed measurements are carried out to create a standardized electronic datasheet of the LEDs, which is then transferred into a modeling software. The design process is thus made more efficient and the number of design errors is minimized. Launch of the products into the market can now be done faster, with better quality and more cost efficiency than before.

A Finnish consortium organized by VTT Technical Research Centre of Finland is using the results of the Delphi4LED project to develop LED luminaires made up of transparent large-area foil. These novel structures enable the achievement of thin, flexible light source for display and lighting applications. For instance, a multi-colored video screen can be incorporated between curved or planar glass surfaces.

Philips Lighting from the Netherlands coordinates the project. Technische Universiteit Eindhoven from the Netherlands; Havells Sylvania Lighting Belgium from Belgium; Magillem Design Services SAS, Ingélux, PISEO, Philips France and Ecce'Lectro from France; Budapest University of Technology & Economics and Mentor Graphics Hungary from Hungary; Mentor Graphics UK from the United Kingdom; and Pi Lighting SARL from Switzerland are the other partners in the consortium.