Aug 2 2016

Scientists are installing new mirrors to improve the quality of the X-ray laser beam at the Department of Energy’s SLAC National Accelerator Laboratory.

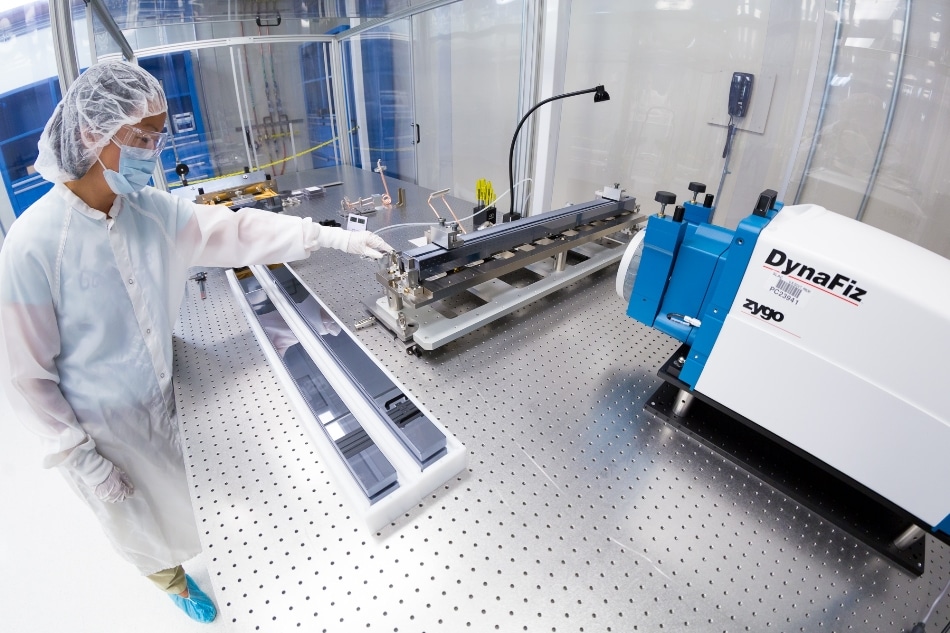

May Ling Ng, SLAC engineer, makes adjustments to the mirror restraints during a test of the holding system’s effect on mirror shape. These measurements are needed to maintain the flatness of the mirror within one atom over the entire one-meter length. (Credit: SLAC National Accelerator Laboratory)

May Ling Ng, SLAC engineer, makes adjustments to the mirror restraints during a test of the holding system’s effect on mirror shape. These measurements are needed to maintain the flatness of the mirror within one atom over the entire one-meter length. (Credit: SLAC National Accelerator Laboratory)

The meter-long mirrors are the ultimate in flatness, smooth to within the height of one atom or one-fifth of a nanometer.

If Earth had the same surface, the hills and valleys would only vary by the width of a pencil, says Daniele Cocco, engineering physicist and head of the optics group at SLAC’s Linac Coherent Light Source (LCLS), a DOE Office of Science User Facility.

Right now, the mirrors are stored in a clean room to avoid dust and prevent damage. Cocco and other engineers only handle the mirrors while wearing gowns, hairnets, masks and gloves. They’re testing the mirrors to see how they will respond to heat and mechanical stress while the beam is running. Both cause tiny deformations on the surface, and even changes as small as half a nanometer can cause big problems.

Five of these mirrors will be installed in LCLS by the beginning of next year and available for experiments in summer 2017. The new arrivals will join the 12 flat and curved mirrors that currently steer and focus light at LCLS, which is almost one mile long. Eventually, the upgraded mirror system will have a total of 28 mirrors.

This is the first time the mirrors have been replaced at LCLS. The original mirrors were installed in 2009, when the free-electron laser came online.

As the laser strikes the mirrors, some degradation of the reflective surface occurs over time. Since the originals were built, there have been improvements in how the mirrors are made, and engineers also better understand how the mirrors can be tailored to the LCLS beam.

When light hits the reflective surfaces, the photons slant toward a specific point. The X-rays are shaped to the need of the experiment, from a focal spot less than a micron in diameter to as wide as a few millimeters. The beam quality also must be preserved in order to reveal the state of molecules and atoms during a range of processes that occur in biology, chemistry, materials science, and energy.

“Time is lost when a beam isn’t perfectly uniform, and you’re not able to find the perfect spot on the sample,” Cocco says. “With mirrors this precise, it’s much easier.”

A Japanese optics company, JTEC Corporation, fabricates the mirrors for synchrotrons and other X-ray laser research facilities such as Japan’s Spring-8 Angstrom Compact Free-Electron Laser (SACLA) and the European X-ray Free-Electron Laser (EXFEL), located in Hamburg, Germany and due to come online in 2017.

Each mirror is made from an individual silicon crystal, artificially grown in a lab. After the mirror is polished with conventional techniques, the company uses a process called elastic emission machining, where a jet of ultra-pure water containing fine particles removes any remaining imperfections atom by atom.

Blemishes in the mirror can create imperfections in the X-ray beam.

“These latest mirrors preserve the beam quality within 97 percent, and the manufacturing technology is continuing to get better,” Cocco says.

With a coherent laser beam, such as the one at LCLS, photons traveling at fixed wavelengths have a specific relationship to each other.

“It’s not random. The light propagates as a perfect wave,” Cocco says. “Even minimal bumps alter the properties of the beam, irreversibly destroying the perfection of the wavefront.”

The light beam also travels over a long distance, which means any disruption can amplify.

Two of the mirrors will be installed adjacent to the front end of the undulator hall at LCLS. The other three will be located 200 meters further down the beam line, in the X-ray transport tunnel between the near and far halls.

The mirrors will also be able to handle the higher energy range of LCLS-II, the next generation of SLAC’s X-ray laser.

Source: https://www6.slac.stanford.edu/